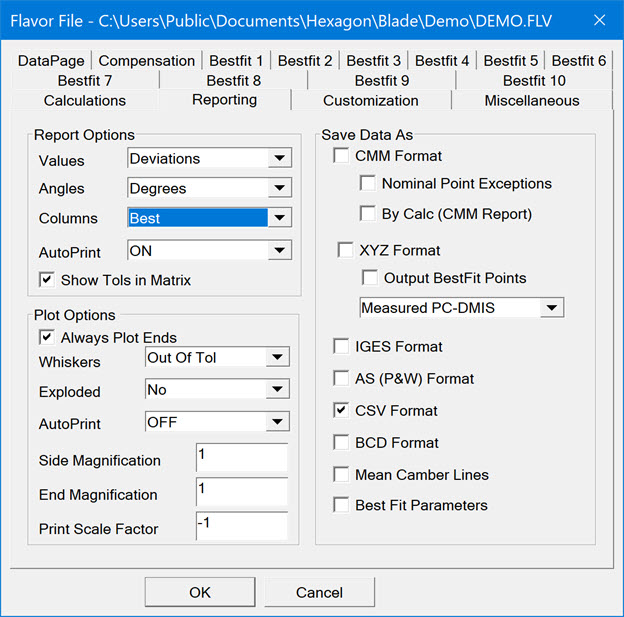

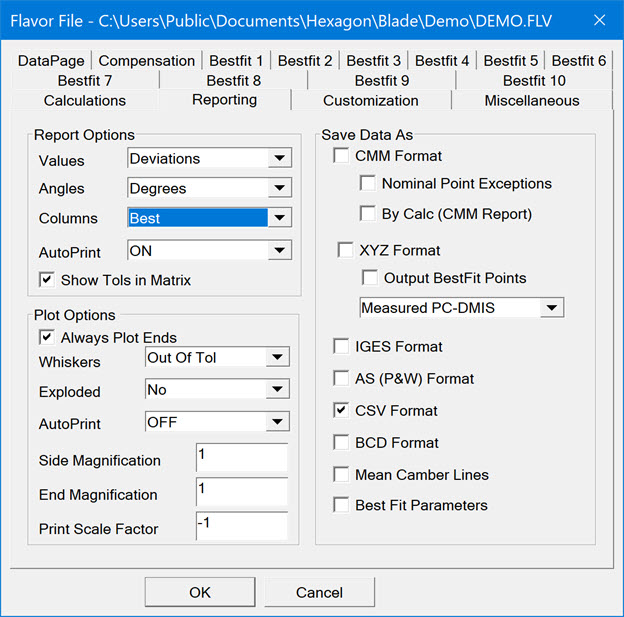

PC-DMIS Blade can output measurement results and data in various formats. The reports and other outputs can be setup in the Reporting tab of the Flavor File dialog box.

Flavor File dialog box - Reporting tab

You can create two main types of reports:

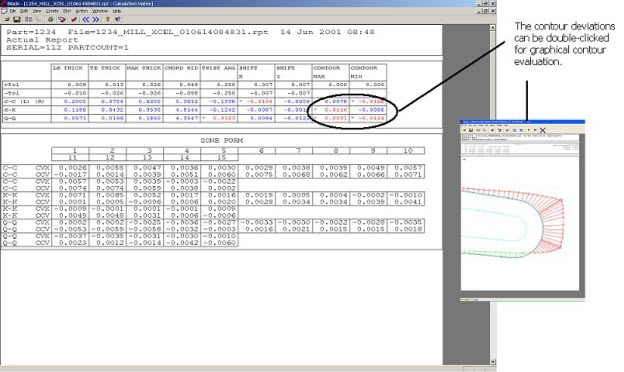

Matrix Report (RPT) - The Matrix report is the standard one-page PC-DMIS Blade report in a tabular spreadsheet form, which provides a look at part deviations. To modify the values of calculations, change options under the Report Options area of the Reporting tab.

CMM Report (CMM) - This option output values in a similar report generated for a PC-DMIS measurement routine after you measure a part on CMM.

Usually, the calculations are grouped by section. You can select to output values of calculations of all sections grouped by calculation type. To do this, mark the By Calc (CMM Report) check box.

!******* Start of Example CMM File ******************

Report from Y:\BladeRunner\blades\1234\1234.rpt

SERNO =

1

OPERATION =

TEST

CMM =

BROWNSHARPE

PARTCOUNT =

1

Actual Nominal Deviation +Tol -Tol OutTol

Section B-B

LE THICK 0.2860 0.1804 0.1056 0.0139 -0.0137 0.0917

TE THICK 0.2108 0.1191 0.0917 0.0198 -0.0290 0.0719

MAX THICK 1.0895 0.9634 0.1262 0.0325 -0.0327 0.0936

CHORD WID 7.0645 6.9211 0.1434 0.0620 -0.0762 0.0814

TWIST ANG -0.0117 0.0000 -0.0117 0.2500 -0.2500

----*----

SHIFT -0.0014 0.0000 -0.0014 0.0064 -0.0064

---*-----

SHIFT 0.0040 0.0000 0.0040 0.0064 -0.0064

-------*-

Section D-D

LE THICK 0.2282 0.1135 0.1148 0.0078 -0.0078 0.1069

TE THICK 0.1772 0.0774 0.0997 0.0090 -0.0212 0.0908

MAX THICK 0.7394 0.6107 0.1286 0.0202 -0.0202 0.1085

CHORD WID 7.0472 6.9154 0.1318 0.0677 -0.0705 0.0641

TWIST ANG -0.0367 0.0000 -0.0367 0.2500 -0.2500

---*-----

SHIFT -0.0018 0.0000 -0.0018 0.0189 -0.0189

----*----

SHIFT -0.0051 0.0000 -0.0051 0.0189 -0.0189

---*-----

Section F-F

LE THICK 0.1788 0.0525 0.1263 0.0060 -0.0060 0.1203

TE THICK 0.1235 0.0372 0.0864 0.0027 -0.0113 0.0836

MAX THICK 0.4111 0.2842 0.1269 0.0094 -0.0094 0.1175

CHORD WID 7.0324 6.9143 0.1181 0.0688 -0.0694 0.0493

TWIST ANG -0.0301 0.0000 -0.0301 0.2500 -0.2500

---*-----

SHIFT 0.0050 0.0000 0.0050 0.0200 -0.0200

-----*---

SHIFT -0.0136 0.0000 -0.0136 0.0200 -0.0200

-*-------

!******* End of Example CMM File ******************

XYZ - This option output values in XYZIJK format in text file. Select XYZ Format in the Save Data As area. You can choose to output the type of values from the list. If required, the output in this format can be imported in PC-DMIS.

IGES - This option outputs a standard IGES file of blade measurements. The file should import into all CAD packages.

AS (P&W) Format - This option outputs values in the P&W format (An OEM-specific Airfoil Surface file). The data is filtered to 112 points per section.

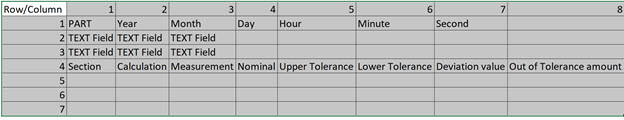

CSV Format - This option generates a CSV (comma-delimited text) file as part of the analysis.

BCD Format - This option output values in the Ball Center Data format (an OEM-specific airfoil surface file). The data is not filtered.

Mean Camber Lines - This option outputs an ASCII text file that represents the mean camber line (MCL) of the airfoil, all sections included.

Best Fit Parameters

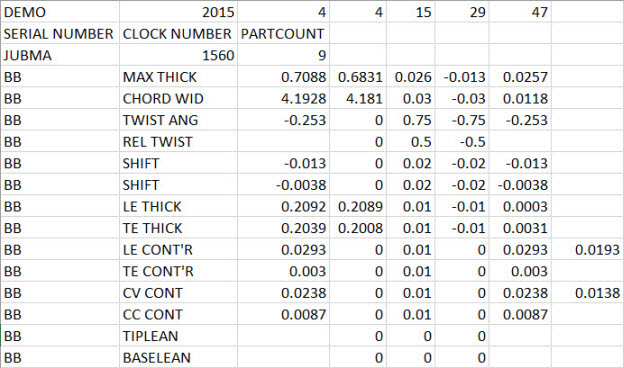

Matrix Report

Example of a Matrix report

Standard CMM Report

!******* Start of Example CMM File ******************

Report from Y:\BladeRunner\blades\1234\1234.rpt

SERNO =

1

OPERATION =

TEST

CMM =

BROWNSHARPE

PARTCOUNT =

1

Actual Nominal Deviation +Tol -Tol OutTol

Section B-B

LE THICK 0.2860 0.1804 0.1056 0.0139 -0.0137 0.0917

TE THICK 0.2108 0.1191 0.0917 0.0198 -0.0290 0.0719

MAX THICK 1.0895 0.9634 0.1262 0.0325 -0.0327 0.0936

CHORD WID 7.0645 6.9211 0.1434 0.0620 -0.0762 0.0814

TWIST ANG -0.0117 0.0000 -0.0117 0.2500 -0.2500

----*----

SHIFT -0.0014 0.0000 -0.0014 0.0064 -0.0064

---*-----

SHIFT 0.0040 0.0000 0.0040 0.0064 -0.0064

-------*-

Section D-D

LE THICK 0.2282 0.1135 0.1148 0.0078 -0.0078 0.1069

TE THICK 0.1772 0.0774 0.0997 0.0090 -0.0212 0.0908

MAX THICK 0.7394 0.6107 0.1286 0.0202 -0.0202 0.1085

CHORD WID 7.0472 6.9154 0.1318 0.0677 -0.0705 0.0641

TWIST ANG -0.0367 0.0000 -0.0367 0.2500 -0.2500

---*-----

SHIFT -0.0018 0.0000 -0.0018 0.0189 -0.0189

----*----

SHIFT -0.0051 0.0000 -0.0051 0.0189 -0.0189

---*-----

Section F-F

LE THICK 0.1788 0.0525 0.1263 0.0060 -0.0060 0.1203

TE THICK 0.1235 0.0372 0.0864 0.0027 -0.0113 0.0836

MAX THICK 0.4111 0.2842 0.1269 0.0094 -0.0094 0.1175

CHORD WID 7.0324 6.9143 0.1181 0.0688 -0.0694 0.0493

TWIST ANG -0.0301 0.0000 -0.0301 0.2500 -0.2500

---*-----

SHIFT 0.0050 0.0000 0.0050 0.0200 -0.0200

-----*---

SHIFT -0.0136 0.0000 -0.0136 0.0200 -0.0200

-*-------

!******* End of Example CMM File ******************

CMM Report by Calc

!******* Start of Example CMM File ******************

Report from Y:\BladeRunner\blades\1234\1234.rpt

SERNO = 1

OPERATION = TEST

CMM = BROWNSHARPE

PARTCOUNT = 1

Actual Nominal Deviation +Tol -Tol OutTol

Calculation LE THICK

BB 0.2860 0.1804 0.1056 0.0139 -0.0137 0.0917

DD 0.2282 0.1135 0.1148 0.0078 -0.0078 0.1069

FF 0.1788 0.0525 0.1263 0.0060 -0.0060 0.1203

Calculation TE THICK

BB 0.2108 0.1191 0.0917 0.0198 -0.0290 0.0719

DD 0.1772 0.0774 0.0997 0.0090 -0.0212 0.0908

FF 0.1235 0.0372 0.0864 0.0027 -0.0113 0.0836

Calculation MAX THICK

BB 1.0895 0.9634 0.1262 0.0325 -0.0327 0.0936

DD 0.7394 0.6107 0.1286 0.0202 -0.0202 0.1085

FF 0.4111 0.2842 0.1269 0.0094 -0.0094 0.1175

Calculation CHORD WID

BB 7.0645 6.9211 0.1434 0.0620 -0.0762 0.0814

DD 7.0472 6.9154 0.1318 0.0677 -0.0705 0.0641

FF 7.0324 6.9143 0.1181 0.0688 -0.0694 0.0493

Calculation TWIST ANG

BB -0.0117 0.0000 -0.0117 0.2500 -0.2500 ----*----

DD -0.0367 0.0000 -0.0367 0.2500 -0.2500 ---*-----

FF -0.0301 0.0000 -0.0301 0.2500 -0.2500 ---*-----

Calculation SHIFT

BB -0.0014 0.0000 -0.0014 0.0064 -0.0064 ---*-----

BB 0.0040 0.0000 0.0040 0.0064 -0.0064 -------*-

DD -0.0018 0.0000 -0.0018 0.0189 -0.0189 ----*----

DD -0.0051 0.0000 -0.0051 0.0189 -0.0189 ---*-----

FF 0.0050 0.0000 0.0050 0.0200 -0.0200 -----*---

FF -0.0136 0.0000 -0.0136 0.0200 -0.0200 -*-------

!*******End of Example CMM File ******************

XYZ File

!******* Start of Example XYZ File ******************

XYZIJK

0.49532,-0.91953,1.72200,-0.92495,-0.37926,-0.02494

0.4926,-0.91295,1.72200,-0.92355,-0.38270,-0.02461

0.48711,-0.89984,1.72200,-0.92209,-0.38621,-0.02414

0.48161,-0.88671,1.72200,-0.92209,-0.38624,-0.02392

0.45959,-0.83425,1.72200,-0.92122,-0.38835,-0.02295

0.43728,-0.78192,1.72200,-0.91854,-0.39474,-0.02169

0.41453,-0.72976,1.72200,-0.91479,-0.40342,-0.02030

0.36712,-0.62632,1.72200,-0.90374,-0.42774,-0.01724

0.31582,-0.52476,1.72200,-0.88373,-0.46781,-0.01357

0.25912,-0.42610,1.72200,-0.85244,-0.52273,-0.00952

0.19566,-0.33170,1.72200,-0.80959,-0.58697,-0.00543

0.12424,-0.24316,1.72200,-0.74883,-0.66276,-0.00130

!******* End of Example XYZ File ******************

AS Format

!******* Start of Example AS File ******************

TITLE: HEXAGON 1234.rpt S/N: hv

COMMENT PARTCOUNT=1

ENGLISH(IN)/METRIC(MM) INDICATOR :IN-P

REFERENCE AIRFOIL TYPE : 1

AERO REF. LINE CANT ANGLE (DEG) : 0.0000

NUMBER OF AIRFOILS : 1

TOTAL NUMBER OF SURFACE PROFILES : 1

SURFACE PROFILE NUMBER : 1

EXTERNAL SURFACE PROFILE TITLE :EXTERNAL

PROFILE CONDITION (HOT/COLD) :COLD

COATING CONDITION (BARE/COATED) :COATED

COATING THICKNESS AND DENSITY : 0.038850 0.000000

TOTAL NUMBER OF SECTIONS : 5

NUMBER OF POINTS PER SECTION : 112

SPLINE REGION INDICATOR : 0

REF. SURF.(PLANAR/CONICAL/RANDOM):RANDOM

SECTION NUMBER : 1

SECTION TITLE : E-E

REFERENCE RADIUS : 0.438000

REFERENCE CONE ANGLE (DEG) : 0.000000

NOSE POINT (X,Y,S) : -0.304300 0.371400 0.438200

TAIL POINT (X,Y,S) : 0.421500 -0.435500 0.437700

SECTION COORDINATES (X,Y,S) : -0.304300 0.371400 0.438200

: -0.291700 0.377900 0.438100

: -0.285300 0.380100 0.437900

: -0.265100 0.381700 0.438100

: -0.258600 0.380600 0.438200

: -0.251900 0.378700 0.438300

: -0.245200 0.375800 0.438200

: -0.239400 0.372200 0.438200

: -0.233800 0.368000 0.438000

: -0.223700 0.358000 0.438000

: -0.215200 0.348100 0.438000

: -0.206900 0.338200 0.438100

: -0.198300 0.328100 0.438200

: -0.181200 0.308200 0.438200

: -0.168200 0.293400 0.438200

!******* End of Example AS File ******************

CSV File

Example of a partial CSV file in a table

BCD File

!******* Start of Example BCD File ******************

Radius 0.058900

BB 113

-1.86770 -0.91500 4.86800

-1.88230 -0.90320 4.86800

-1.89450 -0.88880 4.86800

.......

GG 6

-1.67820 -0.04370 12.18390

-1.69300 -0.03230 12.18390

-1.70500 -0.01670 12.18390

.......

MM 6

-1.41160 0.95210 19.49990

-1.41200 0.96340 19.50030

-1.40970 0.98150 19.50030

.......

!******* End of Example BCD File ******************

Mean Camber Line

!******* Start of Example MCL File ******************

NUMSECT 32

A-A NOMINAL 100

-2.618425, -0.370036, 53.000000

-2.510638, -0.370590, 53.000000

-2.402865, -0.368996, 53.000000

-2.295176, -0.364326, 53.000000

-2.187662, -0.356669, 53.000000

-2.080362, -0.346410, 53.000000

-1.973214, -0.334676, 53.000000

-1.866185, -0.321901, 53.000000

-1.759267, -0.308235, 53.000000

-1.652441, -0.293858, 53.000000

-1.545695, -0.278904, 53.000000

-1.439029, -0.263386, 53.000000

-1.332448, -0.247301, 53.000000

-1.225954, -0.230647, 53.000000

-1.119550, -0.213421, 53.000000

!******* End of Example MCL File ******************