This topic covers the available Best Fit Alignment solution methods when you define a Best Fit Alignment.

The Best Fit Alignment minimizes deviations between measured point data and nominal point data. The features you use in the alignment require correct nominal values in their THEO fields.

The alignment methods below minimize the deviations in different ways:

Method 1: Least Squares Fit

Command Mode: LEAST_SQR

Description: The Least Squares algorithm aligns the two point sets. It does this by transforming the measured points in such a way that it minimizes the sum of the squared distances (between matching measured and nominal points). This is the same as minimizing the average squared error. To understand how the Least Squares alignment works, visualize a spring (of initial length zero) between each measured point and its nominal counterpart. As the distance between the two points increases, the springs stretch. The point set's final position when you release it and let the springs act is the solution to the Least Squares alignment problem.

When to Use It: Use Least Squares to reverse engineer parts and to troubleshoot manufacturing processes, when aligning to feature centers. These feature centers come from regular features such as circles or cylinders.

Least Squares is the most common best fit type because it produces very repeatable results. Least Squares is also used to troubleshoot the manufacturing process, because it gives a better representation of all the point data, rather than just the most extreme points (see the Min Max description below). Least Squares is not ideal for complex surfaces where data is a set of points with unique vectors. In that case, a Vector Least Squares fit is a better option.

Other Info: This is the default. Least Squares works with 2D, 3D, and User Defined best fit alignments.

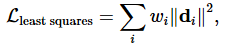

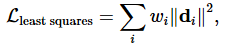

Algorithm: The least squares algorithm minimizes the sum of the squared lengths of the deviations, meaning it minimizes the following mathematical function:

where

are the weights.

are the weights.

Method 2: Vector Least Squares Fit

Command Mode: VECTOR_LST_SQR

Description: The Vector Least Squares fit is a kind of Least Squares fit, except that it projects the error vectors onto the nominal vectors. It then uses these projected distances in the Least Squares fit. A vector fit type allows points to "slide" along the surface but discourages them from pulling away from the surface. All errors are along the nominal vectors.

When to Use It: Use Vector Least Squares to reverse engineer parts and to troubleshoot manufacturing processes, when aligning to surfaces. These surfaces might be regular features, such as circles or cylinders, or they might be irregular complex surfaces. The surface may be represented as a set of points with unique vectors.

For instance, suppose the points are on the surface of a car hood. In this case, motion along the surface is not as important as motion perpendicular to the surface. Therefore we use a vector fit to only measure deviations perpendicular to the surface.

Other Info: This is also known as Projected Least Squares. Vector Least Squares works with standard 2D and 3D best fit alignments, not User Defined best fit alignments.

Suppose you have a nominal point of 1,1,1 with a vector of 0,0,1, with measured values of 4,2,0.95. With this fit, the software adjusts the measured data to 1,1,0.95, and snaps it to the vector of 0,0,1.

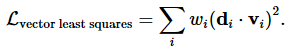

Algorithm:

The vector least squares algorithm minimizes the sum of the squared projected

deviations, where the deviations are projected onto the nominal vectors

, meaning it minimizes the following function:

, meaning it minimizes the following function:

Method 3: Min Max Fit

Command Mode: MIN_MAX

Description: A Min Max fit minimizes the maximum error (the largest distance) among the features being fit.

When to Use It: Use Min Max to evaluate Position tolerances according to the ASME and ISO standards, when tolerancing feature centers. These feature centers come from regular features, such as circles or cylinders.

The Min Max algorithm applies simultaneous diametric tolerance zones to the feature centers. Min Max fit types comply with ASME Y14.5 and ISO 1101.

Min Max fits are very sensitive to measurement uncertainty. A single bad feature can affect the alignment results drastically.

The recommended input feature types for Min Max fits to evaluate position tolerances are: circles, spheres, cylinders, and cones. Min Max is not ideal for complex surfaces where data is a set of points with unique vectors. In that case, a Vector Min Max fit is a better option.

Other Info: Min Max works with 2D and 3D best fit alignments, not User Defined best fit alignments.

Algorithm: The Min Max algorithm minimizes the maximum deviation length, meaning it minimizes the following function:

Method 4: Vector Min Max Fit

Command Mode: VECTOR_MIN_MAX

Description: The Vector Min Max fit is a kind of Min Max fit, except that it projects the error vectors onto the nominal vectors. It then uses these projected distances in the Min Max fit.

A vector fit type allows points to "slide" along the surface but discourages them from pulling away from the surface. All errors are along the nominal vectors. A Min Max fit minimizes the maximum deviation (the largest distance) among the features being fit.

When to Use it: Use Vector Min Max to evaluate Profile tolerances according to the ASME and ISO standards, when tolerancing surfaces. These surfaces might be regular features such as circles or cylinders or they might be irregular complex surfaces. Such surfaces include parts like blades and airfoils. The surface may be represented as a set of points with unique vectors.

For instance, suppose the points are on the surface of a car hood. In this case, motion along the surface is not as important as motion perpendicular to the surface. Therefore we use a vector fit to only measure deviations perpendicular to the surface.

Make sure there is a good initial alignment of the machine to the part. Min Max fit types comply with ASME Y14.5 and ISO 1101.

Other Info: Vector Min Max works with 2D and 3D best fit alignments, not User Defined best fit alignments.

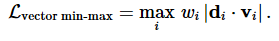

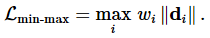

Algorithm: The Vector Min Max algorithm minimizes the maximum projected deviation, so it minimizes the function: