NCi supports the Manual and Read Temperature from Controller temperature compensation modes.

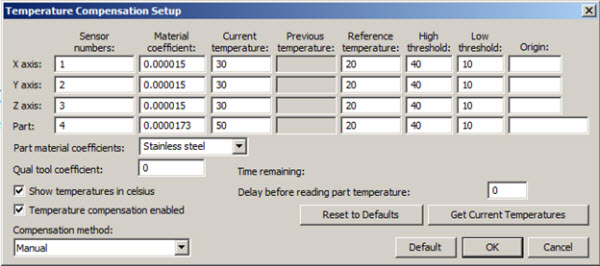

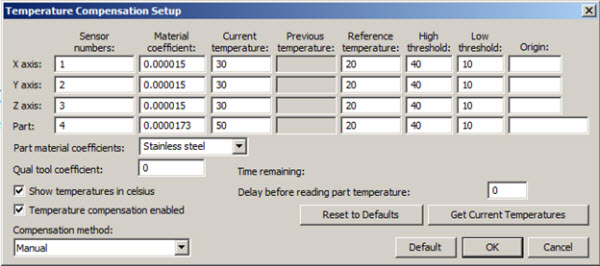

Manual Compensation Mode

In this mode, the Temperature Compensation Setup dialog box appears when you run the measurement routine. The axes and part temperature compensation information includes the current temperatures from the user input, which is used in the temperature compensation computation. You can enter all of the required information in the programming process while you update the current temperature, and then manually confirm your values during the execution process.

You must enter all of the required information related to both axes and the part, including the sensor numbers, as needed.

In this mode, both target and result are adjusted to do the temperature compensation work.

The sensor number values are used for temperature records only.

Temperature Compensation Setup dialog box for Manual mode on NCi systems

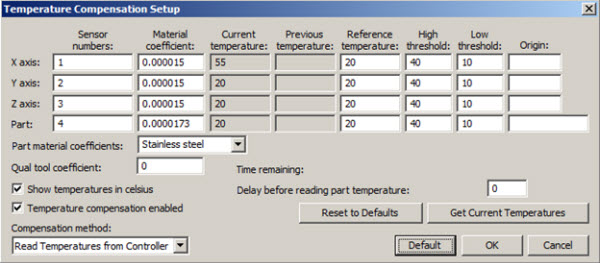

Read Temperatures from Controller Compensation Mode

In this mode, the Temperature Compensation Setup dialog box does not appear when you run the measurement routine. The current temperatures are read from the controller variables. These variables are the variable offset sensor numbers that are based on the variable addresses. The axes and part temperature compensation information includes the sensor numbers. You should correctly define the information during the programming process.

All information related to both axes and part, including the sensor numbers that you manually enter, are required. You are responsible for updating the temperature variables in the controller.

In this mode, both the measurement position and result are adjusted to do the temperature compensation work.

The sensor number values are used as the variable sequence number. They are not used for the temperatures records. PC-DMIS automatically reads these variables as the current temperature.

Temperature Compensation Setup dialog box for Read Temperature from Controller mode on NCi systems

NCi can read and write variables without inserting Feature Measure commands. The example below is provided to test the read and write variables. In prior versions of NCi, the reading and writing of variable functions were only allowed after you measured a feature.

STARTUP = ALIGNMENT/START,RECALL:USE_PART_SETUP,LIST=YES

ALIGNMENT/END

MODE/DCC

FORMAT/TEXT,OPTIONS, ,HEADINGS,SYMBOLS, ;NOM,TOL,MEAS,DEV,OUTTOL, ,

LOADPROBE/TDEBUG

TIP/TIP1, SHANKIJK=0, 0, 1, ANGLE=0

ASSIGN/V1=0

CNC/READVARIABLE,1,V1

CNC/WRITEVARIABLE,8,88

More: