Cancel - This cancels the execution of the measurement

routine.

Cancel - This cancels the execution of the measurement

routine.This is the default execution mode. In this mode, in order to speed up execution, the software ignores any feature calculation errors and proceeds to the next feature. If an error occurs during the execution of the measurement routine, the Execution dialog box displays these two options:

Cancel - This cancels the execution of the measurement

routine.

Cancel - This cancels the execution of the measurement

routine.

Skip - This resumes the execution of the measurement

routine from the next feature. The skipped feature command turns red in

the Edit window.

Skip - This resumes the execution of the measurement

routine from the next feature. The skipped feature command turns red in

the Edit window.

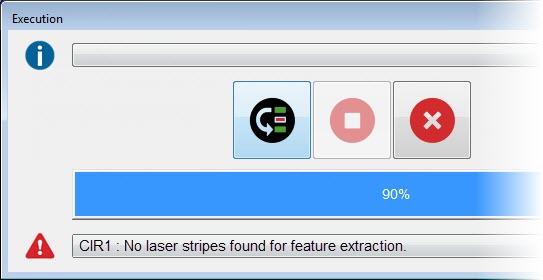

Execution dialog box

Asynchronous Execution Mode Example

Suppose you have three circles in sequence in your measurement routine. This execution mode behaves as follows:

Scan CIR1.

Begin extraction of CIR1 from its pointcloud.

Scan CIR2.

Begin extraction of CIR2 from its pointcloud.

Scan CIR3.

Begin extraction of CIR3 from its pointcloud.

If CIR2 fails to extract, it generates its error, but because the default execution mode continues execution, the calculation error may appear in the Execution dialog box while the machine is already scanning CIR3 or maybe even a later feature. Use Sequential Execution Mode if you want to pause the execution when measurement errors occur.

Using the On Error Command with this Mode

In Asynchronous Execution mode, if PC-DMIS encounters an error, and an On Error command has the Skip parameter defined as shown below, it hides the Execution dialog box and skips the feature that had the error:

ONERROR/LASER_ERROR, SKIP

Unless there are critical errors, the Skip parameter lets the measurement routine execute all the way through without anyone tending it.

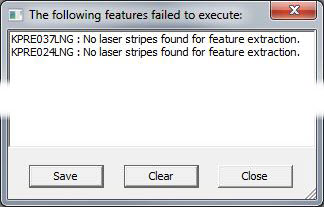

After the entire measurement routine finishes execution, PC-DMIS displays the features that failed to execute in a dialog box. From that dialog box, you can click on any listed feature to locate the feature command in the Edit window and edit it as needed.

List of failed executed features dialog box

For detailed information on the On Error command, see the "Handling Laser Sensor Errors with On Error Command" topic.