You can use the Check Calibration Limits command to check for probe calibration errors and raise alerts during execution. You can combine this command with the On Error command with an error type of "Calibration Outside Limits" to control the execution.

The table shows the descriptions of the errors checked and their bits:

| Error Description | Error Bit |

| Calibration Validity | 1 |

| Calibration Interval | 2 |

| Standard Deviation | 4 |

| Tip Diameter | 8 |

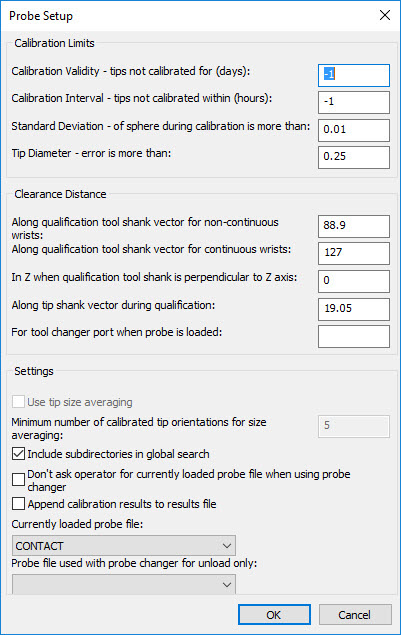

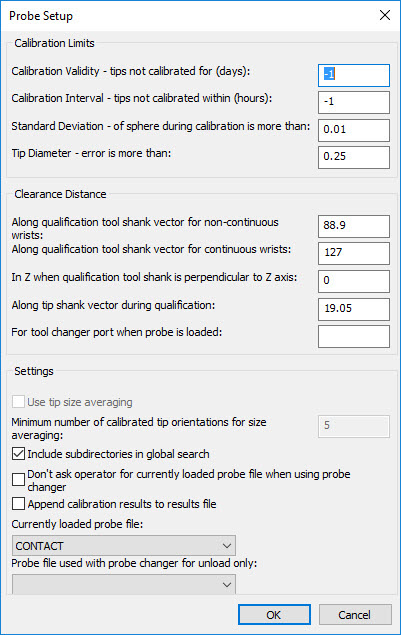

The Probe Setup dialog box provides an ability to set the limits for the above errors.

To open the Probe Setup dialog box, from the Probe Utilities dialog box (Insert | Hardware Definition | Probe), click the Setup button.

Probe Setup dialog box

To set the "Calibration Validity" error, you can type the number of days in the Calibration Validity - tips not calibrated for (days) box. If you set this value to -1, the Check Calibration Limits command does not check for this error.

To set the "Calibration Interval" error, you can type the number of hours in the Calibration Interval - tips not calibrated within (hours) box. If you set this value to -1, the Check Calibration Limits command does not check for this error.

To set the "Standard Deviation" error, you can type the standard deviation value in the Standard Deviation - of sphere during calibration is more than box.

To set the "Tip Diameter" error, you can type the diameter value in the Tip Diameter - error is more than box.