Step 1: Manually Measure an Edge Point

The manual alignment in this example consists of a

single to approximately

locate the part. In later steps, PC-DMIS measures additional datums (under

DCC if applicable) to create a final alignment. Before you begin, mount

the part so it is reasonably square to the axes of the measuring machine.

To measure the datum feature, do the following:

Select the Magnification

tab  and adjust

the magnification until you decrease it to the minimum setting (zoomed

out).

and adjust

the magnification until you decrease it to the minimum setting (zoomed

out).

Select the Illumination

tab  and set

the Top Light to 0% (Off) and the Bottom Light to 35%.

and set

the Top Light to 0% (Off) and the Bottom Light to 35%.

Select the CAD tab.

From the Graphic Modes

toolbar (View | Toolbars | Graphic Modes),

select the Curve Mode button  .

.

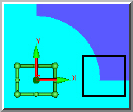

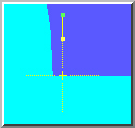

Move the machine so the front-left corner is within the FOV as shown below:

From the Auto Feature

toolbar, click Edge Point to open the Auto Feature (edge point) dialog box.

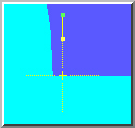

Click a point on the front edge, VERY

CLOSE to the left corner.

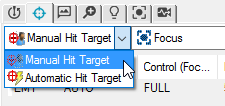

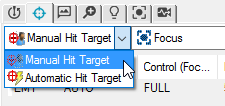

Select the Hit Targets

tab  .

.

Change Automatic Target

to Manual Hit Target.

Since this is actually a "Manual

Target" edge point, the actual point used is where you have physically

placed the crosshair.

Click Create to add

this edge point to the measurement routine.

Click Close to exit

the Auto Feature dialog box.

Next Step ...

![]() and adjust

the magnification until you decrease it to the minimum setting (zoomed

out).

and adjust

the magnification until you decrease it to the minimum setting (zoomed

out).![]() and set

the Top Light to 0% (Off) and the Bottom Light to 35%.

and set

the Top Light to 0% (Off) and the Bottom Light to 35%.![]() .

.