In this Topic Hide

A circularity specification controls how much the feature's cross sections can deviate from a perfect circle. In other words, circularity evaluates how circular the feature is. Circularity is defined from a feature's cross sections.

Actual Value:

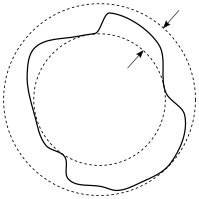

This is the minimum distance between two concentric circles that contain

the entire cross section between them:

The actual value for circularity of a whole feature is the worst actual value of all possible cross sections.

You can use circular, cylindrical, conical, or spherical features that have surface data. For details on the circles, cylinders, cones, and spheres that have surface data, refer to "Feature Types With and Without Surface Data".

Circular features are interpreted as a single cross section.

Measured Value:

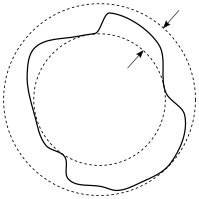

This is the distance between two concentric circles that contain all the

measured points between them. A best-fitting routine defines the center-point

of the circles. Depending on the measurement uncertainty, how many points

you measured, and where you took the points, this can be larger or smaller

than the actual value. Here's an illustrated case where too few points

were measured, so the measured value is smaller than the actual value:

Circularity tolerances on cylindrical features divide up the data into cross sections. The tolerances evaluate circularity on each cross section. The measured value of the entire feature is the measured value of the worst cross section. To maximize your chances of finding the worst actual cross section, we recommend that you measure the cylinder with many cross sections. If you didn't measure the measured data in cross sections, PC-DMIS gives you an error.

Circularity tolerances on conical features divide up the data into cross sections. The tolerances evaluate circularity on each cross section. The measured value of the entire feature is the measured value of the worst cross section. To maximize your chances of finding the worst actual cross section, we recommend that you measure the cone with many cross sections. If you didn't measure the measured data in cross sections, PC-DMIS gives you an error.

An alternate way to evaluate circularity tolerances on conical features is as conicity. Conicity does not divide the data into cross sections. Instead, the measured value is the distance between two coaxial same-angle cones. These cones contain the measured points between them. A best-fitting routine defines the axis and the cone angle. The conicity interpretation is more conservative than the cross-sectional interpretation (the measured values are larger). It does not require the measured data to be measured in cross sections.

In the specification world, circularity of a sphere applies to all cross sections that include the center-point of the sphere—it applies to all the great circles of the sphere. See ASME Y14.5.1 and ISO 1101. However, with most sensor types it is impractical to measure a large number of great circles on a sphere. Therefore, PC-DMIS conservatively approximates the circularity tolerance as a sphericity tolerance. This sphericity tolerance operates on all the data at once. The measured value is the distance between two concentric spheres that contain the measured points between them. A best-fitting routine defines the center-point of the spheres. Thus, PC-DMIS circularity of a sphere is more conservative than the cross-sectional interpretation (the measured values are larger). It does not require the measured data to be measured in cross sections.

None. Circularity tolerances do not allow any modifiers.

The tolerance zone math type controls the best fitting routine:

DEFAULT - This does a minimum-zone best fit (also called min-max). This best fit finds the smallest measured value given the data and the measured-value definition. It is mathematically very similar to the specification, because if you measure the points and cross sections densely and with high accuracy, the measured value closely approximates the actual value.

LSQ - This does a least-squares best fit. It minimizes the sum of the squares of the deviations to a least-squares shape. This option produces a larger measured value (it is more conservative than the DEFAULT option). But in general, this option computes more quickly.

The CIRCULARITY and CONICITY toggle controls the behavior of circularity of a cone.

CIRCULARITY - Evaluates the circularity of each cross section. In the dialog box, you can clear the Conicity check box to use this.

CONICITY - Evaluates the conicity of the entire feature. The conicity interpretation is more conservative than the CIRCULARITY option. In the dialog box, you can mark the Conicity check box to use this.

Here is an example report for a circularity tolerance: