In this Topic Hide

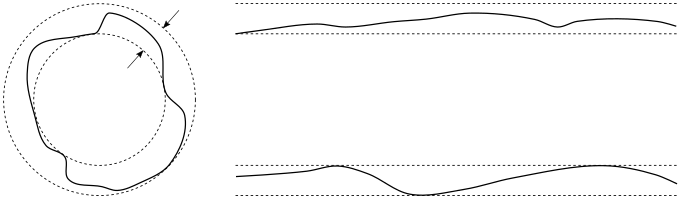

A cylindricity specification controls how much the feature can deviate from a perfect cylinder. In other words, cylindricity evaluates how cylindrical the feature is.

Actual Value:

This is the minimum distance between two concentric cylinders that contain

the entire surface between them:

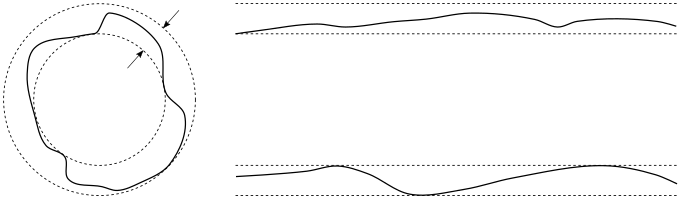

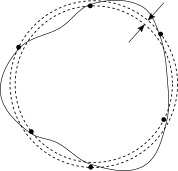

Measured Value:

This is the distance between two concentric cylinders that contain all

the measured points between them. A best-fitting routine defines the axis

of the two cylinders. Depending on the measurement uncertainty, how many

points you measured, and where the you took the points, this can be larger

or smaller than the actual value. Here's an illustrated case where too

few points were measured, so the measured value is smaller than the actual

value:

You can use cylindrical features with surface data. For details on cylinders that have surface data, refer to "Feature Types With and Without Surface Data".

None. This geometric tolerance does not allow modifiers.

The tolerance zone math type controls how to compute the axis of the two concentric cylinders:

DEFAULT - This does a minimum-zone best fit (also called min-max). This best-fit finds the axis of the two concentric cylinders that contain the points between them that has minimum distance between them. Thus, this option produces the smallest measured value to evaluate cylindricity. It is also mathematically very similar to the specification, because if you measure points densely and with high accuracy, the measured value closely approximates the actual value.

LSQ - This does a least-squares best fit. It minimizes the sum of the squares of the deviations to a least-squares cylinder. This option produces a larger measured value (it is more conservative than the DEFAULT option). But in general, this option computes more quickly.

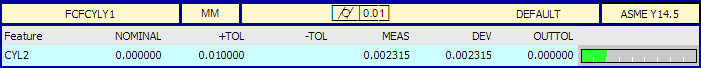

Here is an example report for a cylindricity tolerance: