Basic lathes have no viable C-Axis and cannot measure past the spindle center (X > 0). You can define basic lathes in the NC Server application.

For information on the NC Server operation, please consult the NC Server PDF manual provided with your NC Server application. You can download NC Server from the Universal Updater application.

Do not select rotary tables in PC-DMIS with basic lathes.

The Off-Center Sphere Calibration method records at least three hits (either side and on top) in the XZ plane.

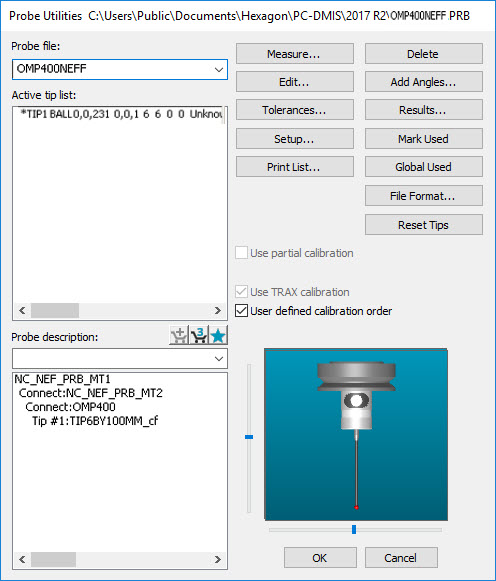

Build the probe tip in the Probe Utilities dialog box as shown below:

Probe Utilities Dialog Box for Off-Center Sphere Calibration

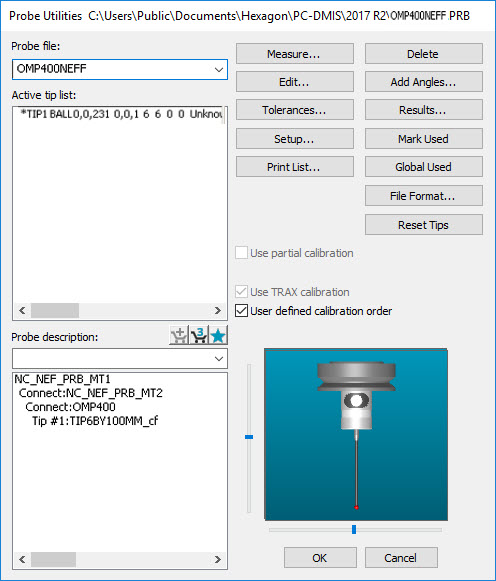

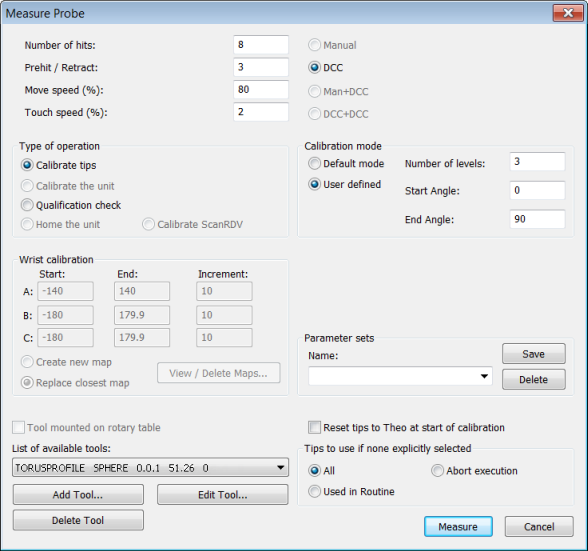

Select the calibration measurement routine and number of hits from the Measure Probe dialog box, as shown below:

Measure Probe Dialog Box for Off-Center Sphere Calibration

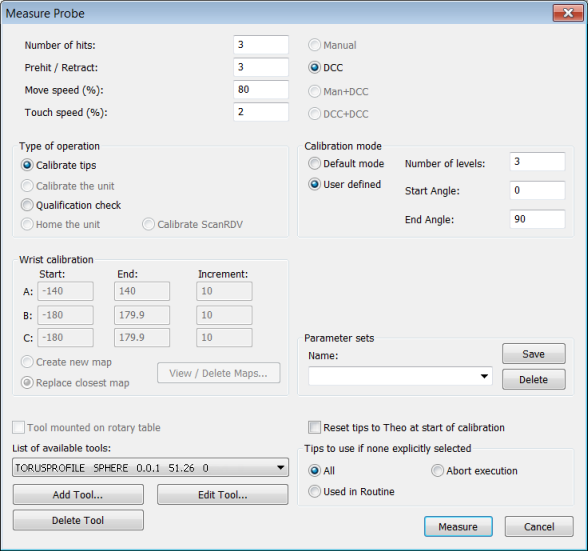

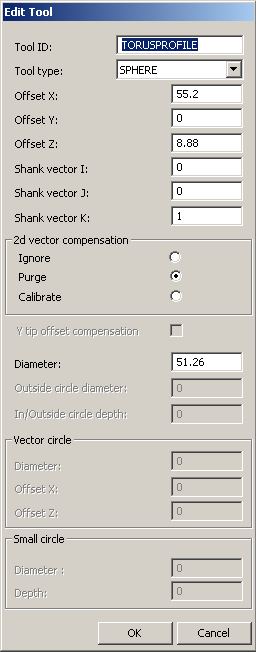

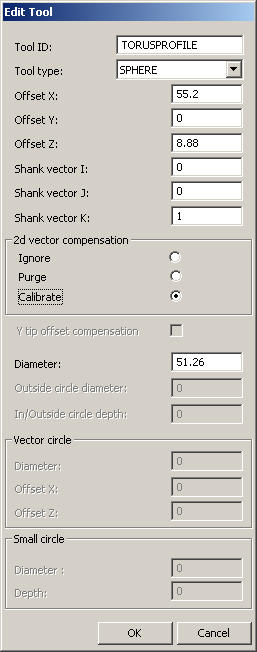

To enter the details of the sphere calibration in the Edit Tool dialog box, click Edit Tool.

Edit Tool Dialog Box for Off-Center Sphere Calibration

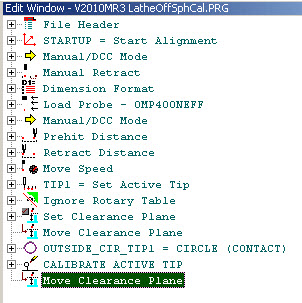

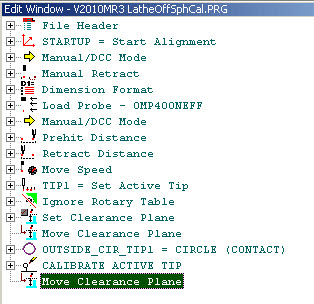

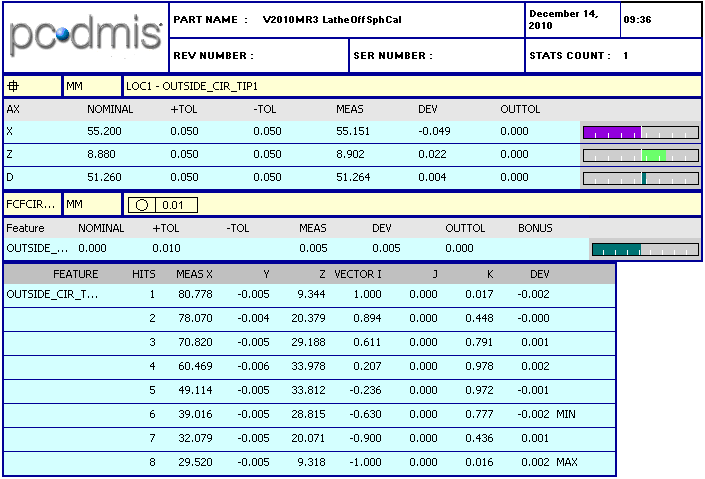

The calibration measurement routine that is created uses a PC-DMIS Auto Circle feature (OUTSIDE_CIR_TIP1) as described below:

Calibration Measurement Routine for Off-Center Sphere Calibration

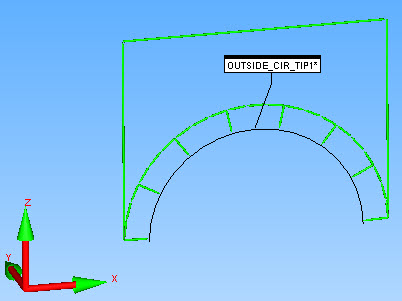

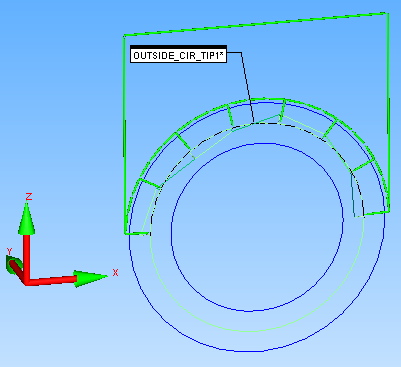

PC-DMIS displays the measurement routine graphically as follows:

Off-Center Sphere Calibration Measurement Routine Graphical View

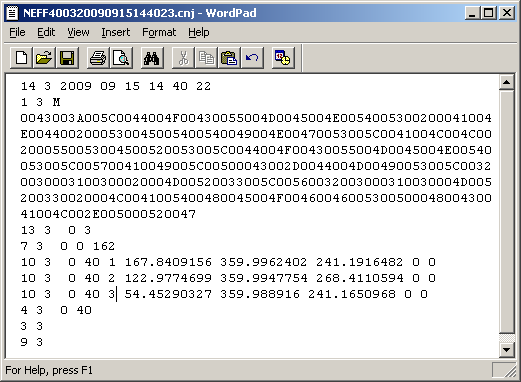

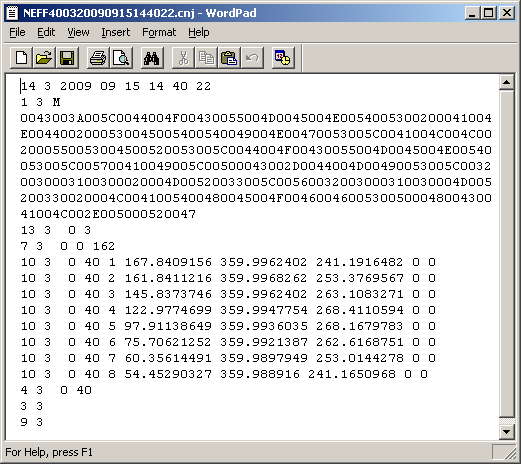

The journal file for a calibration on a section of the Torus profile is shown below.

Off-Center Sphere Calibration Journal Output

The journal file is used to compute and update the Probe Tip Radius, Probe Length, and Probe Tip X Offset.

To open the Edit Probe Data dialog box, click Edit in the Probe Utilities dialog box:

Edit Probe Dialog Box

Offsets in the Y axis are zeroed as it is impossible to compute Y offset information with this form of calibration. The sphere and probe tip must be mounted accurately in the XZ plane. No spindle rotation is needed.

The 2D Vector Calibration measures the profile of a semi-circle in the XZ plane and generates a look-up table to compensate for lobing effect. The selection of eight or more hits and selection of 2D Vector Calibration in the Edit Tool dialog box invokes the Vector Calibration.

Edit Tool for 2D Vector Calibration

The Measure Probe dialog box is shown below for reference:

Measure Probe Dialog Box for 2D Vector Calibration

The Sphere Calibration for the 2D Vector Calibration measurement routine appears unchanged from the Off-Center Sphere Calibration method.

Measurement Routine for 2D Vector Calibration

The Graphical View shows the eight hit points as programmed:

2D Vector Calibration Measurement Routine Graphical View

The journal file is shown below:

2D Vector Calibration Journal File

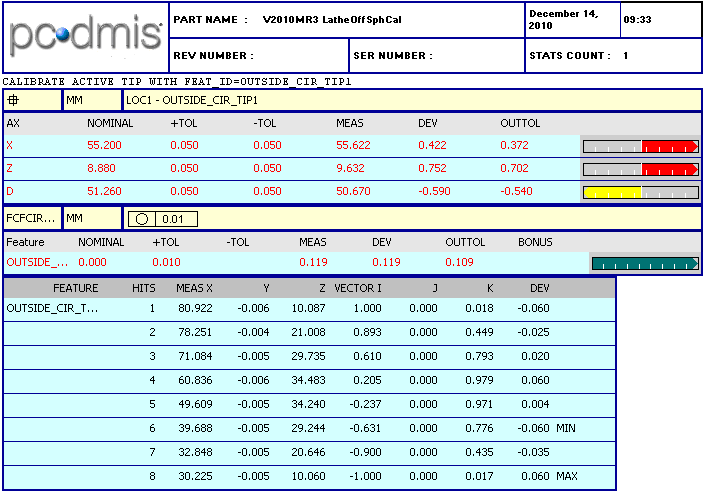

The Report is shown below:

2D Vector Calibration Report

Graphically, the Out of Roundness is drawn in the Graphic Display window as shown below:

2D Vector Calibration Out Of Roundness Graphical View

Running the same journal file after the completion of the Vector Calibration shows an improvement to Circularity due to the 2D Vector Compensation.

Report after 2D Vector Calibration

The Graphical View is then drawn as shown below:

Graphical View after 2D Vector Calibration