Diameter - The value in this box defines the cylinder’s diameter.

Length - The value in this box provides the length (height) of the cylinder's axis. The length parameter is only valid as a nominal. The software does not actually measure the length.

Inner/Outer - This parameter defines whether or not the cylinder is an inner cylinder (hole) or an outer cylinder (including a stud).

Unlike other laser Auto features, for the Overscan value on the Laser Scan Properties tab of the Probe Toolbox, you should use negative values. This limits measurement in the cylindrical region along the cylinder's axis.

Depth - This parameter controls the location of the laser focal point in relation to the cylinder's outside diameter (outer cylinders) or the cylinder's center axis (inner cylinders). This allows you to control how the laser stripes fall on the cylinder's surface because you can specify how far or close the laser is to the cylinder's surface. A depth of 0 for an internal feature means that the center of the laser sensor is on the cylinder's center axis. For an external feature, it is on the surface of the outer cylinder.

A negative depth value moves the laser sensor's center away from the cylinder's surface.

A positive depth value moves the laser sensor's center closer to the cylinder's surface.

Center Offset - This value identifies the center of the cylinder portion of the stud.

Search Length - This value identifies the length of the cylinder portion.

The depth defaults to zero for a plane feature with no extruded edges. You should only change this to a different value if there are specific requirements from your part's drawing. Otherwise, PC-DMIS unsuccessfully attempts to locate points at the specified depth. This results in a feature calculation error from the feature extraction module.

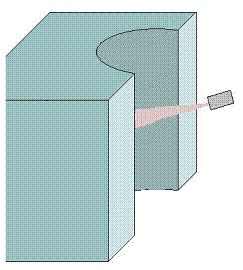

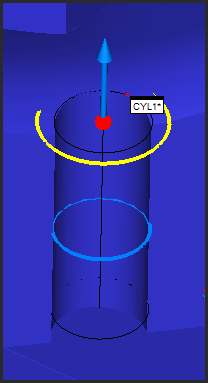

Sample Inner Cylinder

Sample inner Cylinder that shows:

The Depth (blue circle)

The Length (bottom black circle)

The Center Point (yellow circle)

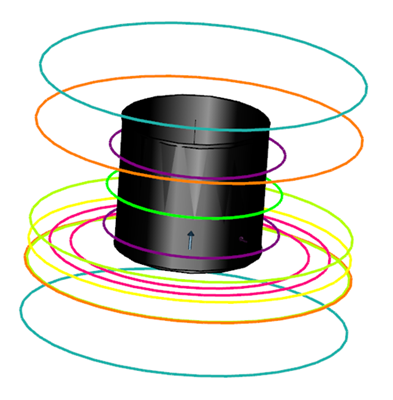

Sample Outer Cylinder

Sample stud Cylinder that shows:

The Search Length (purple circles)

The Center Offset (lime green circle)

The Point Segregation (orange circles)

The Center Point (yellow circle)

The Clipping Plane (light green circles)

The Overscan (sea green circles)

The Ring Band (pink circles)

More: