Many geometric tolerances are meant to be considered simultaneously. For example, when position and/or profile of a surface specifications reference the same partially constrained datum reference frame, you should usually consider them simultaneously. For more details, see the following standards:

ASME Y14.5 [2009] section 4.19

ASME Y14.5 2018 section 7.19

ISO 5458 - 1998

You are responsible to choose which geometric tolerances to consider simultaneously. To do this, you create a simultaneous tolerance command for each set of simultaneous geometric tolerances.

PC-DMIS can consider profile of a line specifications simultaneously so long as they have at least one datum, but this is not recommended. For more details, see "Profile of a Line".

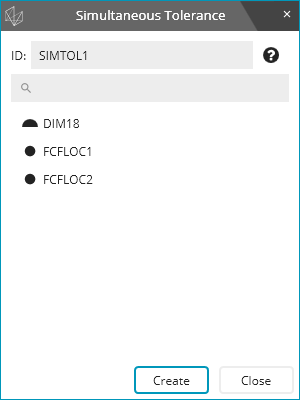

From the menu, choose Insert | Dimension | Simultaneous Tolerance to open the Simultaneous Tolerance dialog box:

Modify the dimension ID if needed.

Select which geometric tolerance commands belong to the simultaneous tolerance.

After you select a geometric tolerance command, the list filters itself so you only see dimensions with the same datum reference frame as the first tolerance command you selected.

In the Edit window, the Command mode syntax looks like this:

SIMTOL2 =SIMULTANEOUS_TOLERANCE/FCFLOC2,FCFLOC5,FCFPROF12,,

As in the dialog box, the only controls in the Edit window are for the dimension ID and which geometric tolerance commands belong to the simultaneous tolerance.

Consider the simultaneous tolerance command as an annotation or directive. Nothing happens if you execute it. It also does not appear in the report. Instead, the simultaneous tolerance command changes how the geometric tolerances are evaluated.

During execution, the geometric tolerance commands know that they belong to the simultaneous tolerance command. They also know which of the other geometric tolerance commands are also part of the simultaneous tolerance command. If you've measured all of the inputs to all of the simultaneous tolerances (so the tolerance is ready to evaluate), the simultaneous calculation takes place. If you haven't measured all the input features, then the tolerance is not ready to evaluate. Is this case, PC-DMIS temporarily shows a "Waiting for evaluation" message in all of the geometric tolerance commands in the simultaneous set. The message identifies which geometric tolerance is causing the delay, and any unmeasured features. Your report temporarily shows "Waiting" as well, instead of a measured value. Once you measure all input features, PC-DMIS updates the Edit window and report with the measured values.

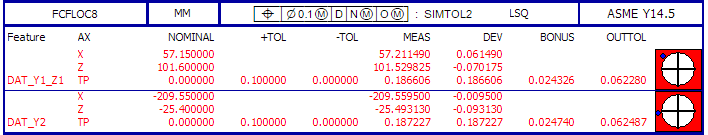

The report for a tolerance that belongs in a simultaneous set looks like this:

The report is essentially the same as any other geometric tolerance. PC-DMIS shows the label in the report in the same place it would be if there were no simultaneous tolerance. You can know if a tolerance was considered simultaneously by the text in the header of the label. For example, in the image above, SIMTOL2 is that text. It indicates which simultaneous tolerance command the geometric tolerance command belongs to.

PC-DMIS does not consider lower segments of composite position or profile tolerances simultaneously. The upper segment is simultaneous with other tolerance commands, but PC-DMIS considers any lower segments independently of everything else.

Your measurement routine does not need any special structure to use simultaneous tolerances. Just be aware that during execution, if PC-DMIS hasn't measured some of the features yet, when it executes the first geometric tolerance in the simultaneous set, it displays a temporary "waiting" message.

The easiest way to avoid this temporary "waiting" message is to measure all of your features first, and then put all of your tolerances after all of your features. This ensures that all tolerances are ready to evaluate, and you never get a "waiting" message.

If you use expressions with your geometric tolerance commands, place them late enough in your routine so that you don't get a "Waiting" result.

PC-DMIS 2020 R2 introduced the simultaneous tolerance (SIMULTANEOUS_TOLERANCE) command. This command works with the new geometric tolerance command. Prior to this, PC-DMIS had the simultaneous evaluation (SIMULTANEOUS_EVALUATION) command. It was designed to work with the XactMeasure command. The new simultaneous tolerance command works differently from the simultaneous evaluation command:

Simultaneous

Evaluation |

Simultaneous

Tolerance |

XactMeasure tolerances were unmarked for execution (blue in the Command Mode edit window). |

Geometric tolerances are marked for execution (white in the Edit window in Command mode). |

XactMeasure tolerances had nothing in the report. |

Geometric tolerances report as usual, and a small note in the report states that they belong to a simultaneous set. |

The simultaneous evaluation report had all of the results from all of the tolerances in the simultaneous set. |

Simultaneous tolerance produces nothing in the report |

If you open a program from version 2020 R1 or earlier, PC-DMIS does the following:

Converts any simultaneous evaluation commands to simultaneous tolerance commands

Converts XactMeasure tolerances to geometric tolerance commands

Marks the geometric tolerance commands for execution (white in the Edit window in Command mode)

If any profile of a line specifications are included in a simultaneous evaluation command, that do not reference any datums, PC-DMIS converts them to profile of a surface.

For additional information on migration, see "Migration from XactMeasure".