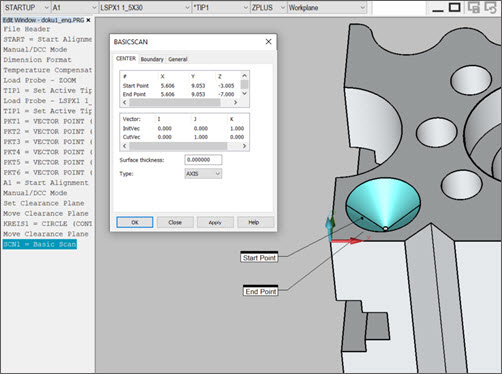

To find a Low/High point in an area, select Insert | Scan | Center. The CENTER tab in the BASICSCAN dialog box appears:

BASICSCAN dialog box - CENTER tab

This tab takes a start point of the scan and an end point and enables the controller to execute the scan. The output from this scan is a single point only.

For the center method, you do not need to set a boundary condition on the Boundary tab.

These parameters control the scan execution:

Start Point: This point is the start point from which the execution starts.

End Point: This point is the end point at which the execution ends.

You can directly type the points or obtain them from the machine or CAD.

Defining a Center Basic Scan

You can define a center basic scan in one of these ways:

Directly type the values. See "Center Basic Scan - Type Values Method".

Physically measure the points on the part. See "Center Basic Scan - Measured Point Method".

Click on the points on the CAD model in the Graphic Display window. See "Center Basic Scan - Surface Data Method" or "Center Basic Scan - Wireframe Data Method".

Once you create the scan, PC-DMIS inserts it into the Edit window. Following is an example of a command line for a center basic scan in the Edit window:

SCN4 =BASICSCAN/CENTER,NUMBER OF HITS=1,SHOW HITS=NO,SHOWALLPARAMS=YES

<5.606,9.053,-3.005>,<5.606,9.053,-7.000>,CutVec=0,0,1,AXIS

InitVec=0,1,0,IN,THICKNESS=0,AVOIDANCE MOVE=NO,DISTANCE=0

FILTER/DISTANCE,2.54

EXEC MODE=RELEARN

BOUNDARY/

HITTYPE/VECTOR

NOMS MODE=MASTER

ENDSCAN

More:

Example of a Center Basic Scan

Center Basic Scan - Type Values Method

Center Basic Scan - Measured Point Method