In this Topic Hide

A total runout specification controls how much the feature can deviate from having perfect form centered on some datum axis.

You can use cylindrical, conical, or planar features that have surface data. For details on the cylinders, cones, and planes that have surface data, refer to "Feature Types With and Without Surface Data". They must be nominally concentric with the datum axis.

Actual Value:

This is the minimum distance between two concentric cylinders that contain

the actual surface between them. The cylinders are concentric with the

actual datum axis.

Measured Value:

This is the minimum distance between two concentric cylinders that contain

all the measured points between them. The cylinders are concentric with

the measured datum axis.

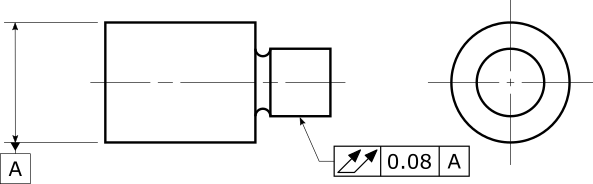

Suppose you had this total runout specification:

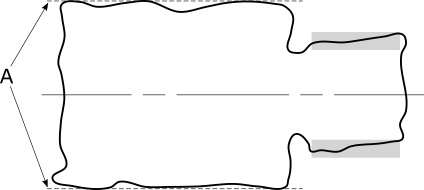

With the above specification, the actual value look like this:

The actual part surface uses the solid line, the actual datum uses the dashed line, and the smallest tolerance zone containing the actual feature surface is shown in the shaded area. The tolerance zone is exactly coaxial to the actual datum axis.

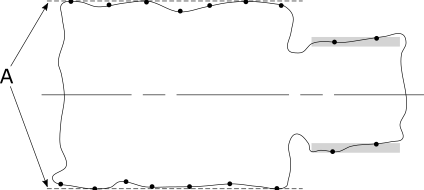

Finally, the measured value (with DEFAULT datum math) looks like this:

The measured tolerance zone is exactly coaxial to the measured datum axis. In this case, the measured points were not measured densely enough, and so the measured value is smaller than the actual value.

Actual Value:

This is the minimum distance between two concentric cones that contain

the entire actual surface between them. The cones are concentric with

the actual datum axis. They also have the same cone angle as the nominal

cone surface.

Measured Value:

This is the minimum distance between two concentric cones that contain

all the measured points between them. The cones are concentric with the

measured datum axis. They also have the same cone angle as the nominal

cone surface.

Actual Value:

This is the minimum distance between two parallel planes that contain the

entire actual surface between them. The planes are perpendicular to the

actual datum axis.

Measured Value:

This is the minimum distance between two parallel planes that contain all

the measured points between them. The planes are perpendicular to the

measured datum axis.

The datum reference frame must establish a clear datum axis.

None. This geometric tolerance does not allow modifiers.

When at least one datum feature has surface data, the datum math type controls how to compute the measured datums from the datum features’ surface data. For more information, see "How PC-DMIS Solves and Uses Datums".

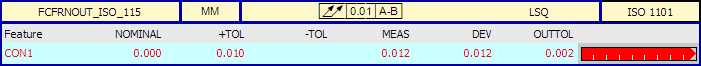

Here is an example report for a total runout tolerance of a cone.