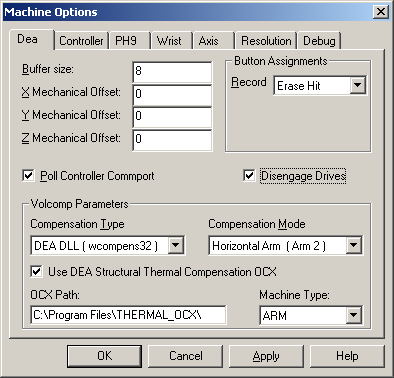

Machine Options dialog box - Dea tab

The Dea tab allows you to configure the following settings that are specific to the DEA interface:

Buffer Size - This is the number of moves that can be sent to the controller buffer at one time. Some machines give errors if we send too many moves in advance so reducing this can help with that. Decreasing this value however also reduces the system performance. For example, if this is set to 1, then PC-DMIS only sends the next move command when the machine has finished the previous one. That causes the machine to pause between moves as each command is sent.

XYZ Mechanical Offset - These values allow you to establish the mechanical offset for your machine. This should only be adjusted by a trained technician.

Button Assignments - You can specify to have the Record button either Erase the Last Hit or act as the End/Done key.

Poll Controller Commport - When this check box is enabled, PC-DMIS periodically polls the serial port to prevent loss of communication. Only select this option if you suspect communication problems.

Disengage Drives - This check box should be selected for DCC machines which have drives that can be disengaged that are going to be used manually.

Compensation Type - Select from the following Volcomp methods: NONE, DEA Standard, DEA DLL (wcompens32), ASI, or Brown & Sharpe.

Compensation Mode - Select from the following compensation modes: Standard Machine, Dual Drive, Horizontal Arm (Arm 1), or Horizontal Arm (Arm 2).

Use DEA Structural Thermal Compensation OCX - Select this option to use DEA Structural Thermal Compensation OCX.

OCX Path - Specifies the path for the DEA Structural Thermal Compensation OCX file.

Machine Type - Specify the type of machine: Arm or Robot

Altering these values may give an undesired result. Only a trained Technician should change these values.