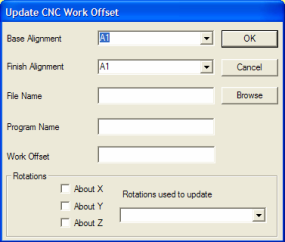

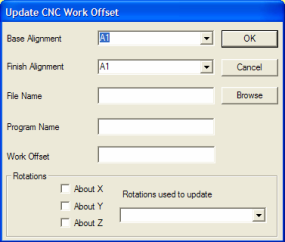

Select Operation | CNC Programming | Update Work Offset to open the Update CNC Work Offset dialog box.

Update CNC Work Offset dialog box

CNC/UPDATEWORKOFFSET,baseAlignment,finishAlignment,fileName,programName,workOffset

This command calculates changes to a work offset and communicates that change to the CNC. The changes are determined by computing the shift of the origin between two PC-DMIS alignments.

Generally, the first alignment (baseAlignment) represents where PC-DMIS NC assumes the work-offset system is located.

The second alignment (finishAlignment) represents the actual location of the work-offset system based on a set of measurements used to generate the second alignment.

baseAlignment should be a PC-DMIS alignment that represents where the work-offset system was prior to the measurements. You can select this from the Base Alignment list in the Update CNC Work Offset dialog box for this command. This list contains the PC-DMIS alignment commands that are available to this point in the PC-DMIS measurement routine.

finishAlignment should be a PC-DMIS alignment that represents where the work-offset system is after the measurements. You can select this from the Finish Alignment list in the Update CNC Work Offset dialog box for this command. This list contains the PC-DMIS alignment commands that are available to this point in the PC-DMIS measurement routine.

fileName is the name of a CNC program file that PC-DMIS NC generates. Some CNC interfaces (for example, Ethernet) upload the work-offset changes directly. In these cases, the fileName parameter is not used. If you do not provide a file extension, the extension, "WRK" appends to the CNC file name.

programName is the CNC macro name of the CNC program that generates. This parameter is not used for interfaces that upload the work-offset changes directly.

workOffset is selected from the Work Offset list in the Update CNC Work Offset dialog box. For Fanuc-style controllers, the values can be from G54 through G59. This option defines the work offsets that will be enabled in the CNC measurement routine.

Rotations

You can apply rotations about base alignment axes to either a physical rotation axis, like a rotary table, or as a rotation of the NC coordinate system (note that many controllers do not have this capability). Select the rotation axes to enable About X, About Y, and/or About Z. You may set the Rotations used to update list to:

None: No rotations

Rotary Axes: Use the standard rule A about X, B about Y, or C about Z to rotate the rotary axis associated with the Cartesian axis. These appear as rotation offsets in the Work Offset area of the control. This updates the standard work offset rotations G54, G55, G56, G57, G58, G59.

Transformation: Apply rotations to the NC Controller’s coordinate system. The changes may show up in a special set of registers in the control (i.e., Fanuc Work Offset Error Compensation registers) or as an extension of the standard work offsets (Siemens 840).

Fanuc - For Fanuc controllers, this updates transformations in Fanuc Registers for Work Offset Compensation:

G54 ----> G54.4 P1

…

G59 ----> G54.4 P6

Base Addresses:

G54.4 P1 X - 26010 Y - 26011 Z - 26012 …

G54.4 P2 – P7 X 26020,26030,26040,26050 …

Enabling Work Offset Compensation in an NC measurement routine: (Example From Fanuc Document Work Piece Setting Error)

G55 (Enable std work offset)

G05.1 Q1 &(AICC AI Contouring Control must be active first)

G54.4 P1 (Enable Work Offset compensation #1)

Siemens - The selected User Frames G54 … G57 are updated for rotation and translation.