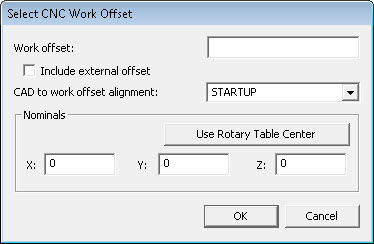

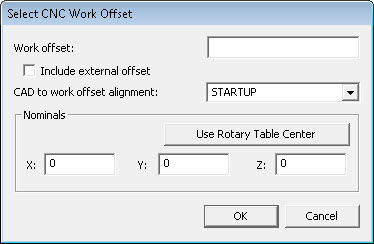

Select Operation | CNC Programming | Use Work Offset to open the Select CNC Work Offset dialog box.

CNC/USEWORKOFFSET,workOffset,alignmentCommand,nomX,nomY,nomZ

This command equates the PC-DMIS alignment with the CNC alignment. CNC alignments are implemented as work-offset coordinate systems.

workOffset can be a string that represents a basic work offset (such as G54-G59). This parameter defines the work offsets that will be enabled in the CNC measurement routine. There is a default work offset defined in the machine's definition that is used after the first commanded motion until the USEWORKOFFSET command specifies another. The Nominals option in the dialog box represents the position of the work offset in machine coordinates. These fields are required when you use a Rotary Table to correctly transform motion and returned point data.

You can use the Include external offset check box to include any external work offsets associated with the measurement routine. Otherwise, the external work offsets are not included.

alignmentCommand can be any alignment defined previously in the measurement routine. This alignment should represent the work-offset alignment in PC-DMIS. In other words, the coordinates for points in the PC-DMIS measurement routine with this alignment should agree with the coordinates of the same points in the CNC measurement routine with the specified work offset applied.

nomX, nomY and nomZ are the expected values for the X, Y and Z axes of the controller. These values represent the offset values in a perfect world. The X, Y and Z values must be entered if a rotary table is present. These values compensate for table rotation.