You can use complex chord zones to define arbitrary, complex tolerance zones on the convex or concave side of a blade. The zones always extend from the leading tip to the trailing tip. The central concept is a "complex zone", which is based on a leading or trailing edge.

Defining a Complex Chord Zone

To define a complex chord zone, follow these steps:

Add the complex chord zone parameter to the Selected List of Calculations and Parameters list on the Calculations tab in the Tolerance file. You can define up to 10 zones (COMPLEX_CHORD_ZONE through COMPLEX_CHORD_ZONE10).

Use one of the following methods to set the parameters for the zone:

Set the tolerances on the Default tab. You can use this tab when the parameters are the same for each zone. In this case, you do not need to define the parameters for each zone.

Customize the zone for each individual section on the individual section tabs. If you select a zone on an individual section tab, you can enter the parameters in the box on the tab. The format inside the text box is something like this:

The interpolation parameters for a complex chord zone interpolate between the specified tolerances. These parameters are SMOOTH, LINEAR, and CONSTANT. The remaining complex chord zone parameters are in a table of three columns and up to fifty rows. The table must have two or more rows. Each row has this format:

X <lower tolerance> <upper tolerance>

The first column, X, is the distance from the tip. If the first distance is zero, that means the zone includes the tip; otherwise the zone does not include the tip. The values are in arbitrary units because the zone always extends from the leading tip to the trailing tip. They can be percentages, distances, or anything that preserves the right ratio to each other.

The second column is the lower tolerance. The lower tolerance value is typically negative.

The third column is the upper tolerance. The upper tolerance value is typically positive.

The upper and lower tolerances can be symmetric, but this is not mandatory.

For the SMOOTH and LINEAR parameters, the plus and minus tolerances in the last row are always used because the zone tolerances interpolate (linearly or smoothly) to the tolerances in the last row.

For the CONSTANT parameter, the last plus and minus tolerances do not matter. More specifically, the zone tolerance is constant over every distance interval. The row where a tolerance is listed contains the distance where the constant zone size starts, and the constant zone size ends at the distance given on the next row. This means that the plus and minus tolerances in the last row have no effect; they can be zero, or some very large value, or anything.

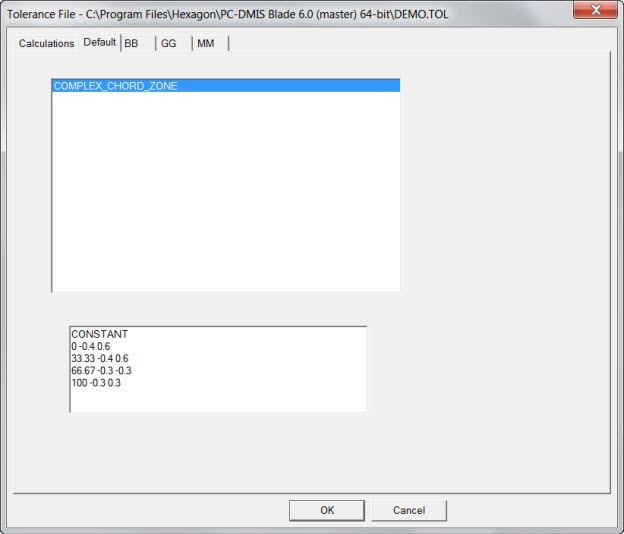

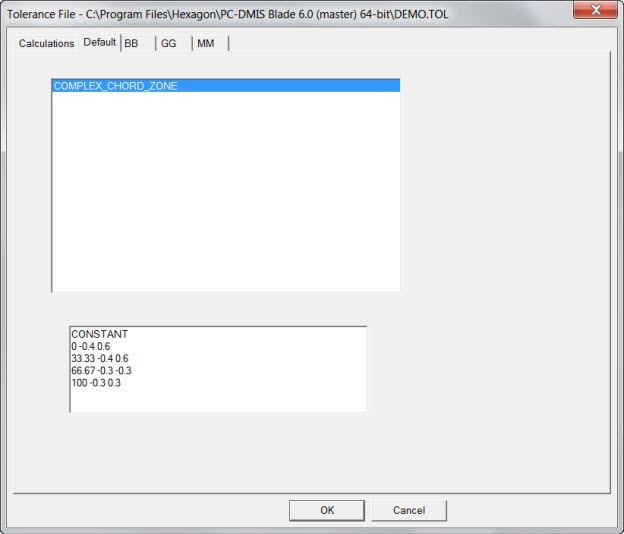

Following is an example of the COMPLEX_CHORD_ZONE parameter that represents the zone. It divides the blade into three equal pieces:

Part (a) is from 0% to 33.33%,

with a tolerance of -0.4 to 0.6.

Part (b) is from 33.33% to 66.67%, with a tolerance of -0.4 to 0.6.

Part (c) is from 66.67% to 100%, with a tolerance of -0.3 to 0.3.

COMPLEX_CHORD_ZONE example

Using a Complex Chord Zone

Once you have defined a complex chord zone, you can use it in a best fit that is defined in the Flavor file. The best fit algorithms for a complex chord zone are:

Concave Least Squares Chord Zone

Convex Least Squares Chord Zone

Concave Min Max Chord Zone

Convex Min Max Chord Zone

Two of the parameters are on the concave side, and the other two are on the convex side. Also, two of them use least squares math, and two of them use min-max math. All of these fits operate on the entire zone at once, and they always fit to the middle of the zone. Also, these fits work well with variable (nonuniform) zones, which is important because typical chord zones are variable (nonuniform).

When you select one of these algorithms in the Flavor file, you must also choose a complex zone number for which complex zone to use (1 through 10). A complex zone best fit always fits to the center of the tolerance zone, which is the same as the nominal curve if the tolerance zone is symmetric. The center of the tolerance zone is different from the nominal curve if the tolerance zone is not symmetric.

A complex chord zone best fit also weights points according to the inverse of their total tolerance. Places where the zone is small get a large weight. Places where the zone is large get a small weight. This means that complex chord zones should never have an exactly zero total tolerance because that would make the weight infinite.

To use a complex chord zone, follow these steps:

Define the best fit algorithms that you want in the Flavor file. To define them, decide whether you want least squares or min max, and whether you want the concave side or the convex side.

Use the CCCONT or CVCONT calculation to define the profile calculations that you want. Use the DEVIATION_RATIO calculation method because the chord zone is typically variable (nonuniform). The DEVIATION_RATIO calculation method tells you the fraction of the zone that was used for the profile.

Values between 0.0 and 1.0 are in tolerance, because they mean the profile fits in the zone.

Values larger than 1.0 are out of tolerance, because they mean the profile does not fit in the zone.

Smaller values are better; larger values are worse.

In the Tolerance file, set the tolerance range to [0.0, 1.0] so that the conformance is correct. Each tolerance goes into the complex chord zone.

Profile Plots

You can plot leading edge least squares fits in Profile Plots. For information about Profile Plots, see "Creating Profile Plots".