In this Topic Hide

A perpendicularity specification controls how much the feature can deviate from a perfect 90 degree angle to a datum. Sometimes you can use a secondary datum to further control the tolerance zone’s orientation.

For this geometric tolerance, these three aspects work together:

Each considered feature and each resulting toleranced feature

Each tolerance zone

The datum features

To evaluate this tolerance, PC-DMIS converts each considered feature to a toleranced feature. You can find this described in "Deriving the Toleranced Feature”.

PC-DMIS then optimizes each toleranced feature into its respective tolerance zone. The optimization process respects whatever constraints each datum imposes.

Each toleranced feature is optimized independently.

You can use these feature types:

cylinders, cones, planes, lines, 3D widths, and 2D widths

Some feature types have a different toleranced feature than the considered feature's surface data. These include 3D constructed BF lines, cylinders, cones, 3D widths, 2D widths, and planes with a tangent plane modifier. For more information, see "Deriving the Toleranced Feature”.

When the considered feature has an axis, the tolerance

zone shape can be diametric (with the tolerance zone shape symbol  ) or planar (no tolerance zone shape symbol). These are

the axial considered features:

) or planar (no tolerance zone shape symbol). These are

the axial considered features:

Cylinder

Cone

Surfaceless axis

For information on the feature command types that correspond to these feature types, see "Feature Types With and Without Surface Data".

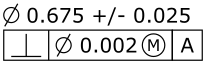

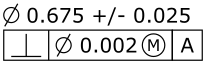

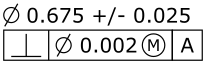

Here is an example of a perpendicularity on a cylinder with a diametric tolerance zone:

Here is an example of a perpendicularity on a cylinder with a planar tolerance zone:

Planar tolerance zones on axial considered features need a specified tolerance zone orientation. This is because the feature does not have enough information to orient the zone correctly. In these cases, the Zone Orientation button in the Geometric Tolerance dialog box becomes visible. For information on how to use this button to change the zone orientation, see "Zone Orientation" in the "Feature Control Frame Tab" topic.

If a tolerance controls the X component of the orientation, the tolerance zone surface normal vector should be X.

When the considered feature is a plane, surface line, 3D width, or 2D width, the tolerance zone shape is always planar. It is oriented parallel to the nominal surface or surfaces.

You can have more than one considered feature, but those features must all be the same type.

Actual

Value:

This is the size of the smallest tolerance zone that contains the actual

toleranced feature. The zone is nominally oriented to the actual datum

or datums.

Measured

Value:

This is the size of the smallest tolerance zone that contains the measured

toleranced feature. The zone is nominally oriented to the measured datum

or datums.

Suppose you have this perpendicularity specification:

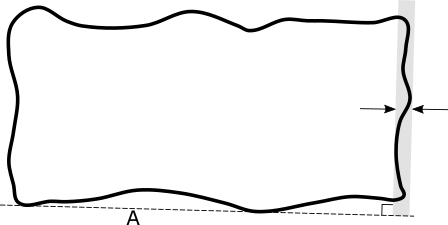

For the above specification, the actual value looks like this:

In the above image, the actual part surface uses the solid line, the actual datum uses the dashed line, and the smallest tolerance zone containing the actual toleranced feature is shown in the shaded area. The tolerance zone is exactly perpendicular to the actual datum.

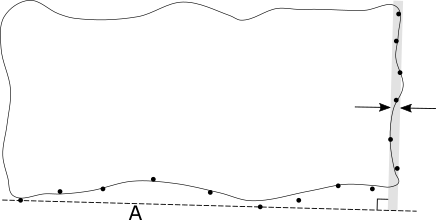

Finally, the measured value (with DEFAULT datum math) looks like this:

In the above image, the measured tolerance zone is exactly perpendicular to the measured datum. In this case, because the measured points were not measured densely enough, the measured value is smaller than the actual value.

The considered feature or features must be nominally perpendicular to the primary datum.

Because of this, all input features (considered and datum) must have the correct specified nominal values. This ensures that the tolerance zone orients correctly based on the datum features. It also ensures that the geometric tolerance command correctly identifies the optimizable degrees of freedom.

For a planar zone on axial features, the datum reference frame must fully constrain the tolerance zone orientation. The planar tolerance zone’s surface normal must be perpendicular to each considered feature's axis vector.

In PC-DMIS version 2020.2 and later, material modifiers on datums are no longer allowed.

When the considered feature

is a cylinder or a width, perpendicularity allows a maximum material modifier

to indicate

the specification is at the maximum material condition (MMC). Alternatively,

it allows a least material modifier

to indicate

the specification is at the maximum material condition (MMC). Alternatively,

it allows a least material modifier  to indicate

the specification is at the least material condition (LMC). This means

that as the unrelated mating envelope size (or unrelated minimum material

envelope size for LMC) deviates from the MMC (or LMC), additional tolerance

or "bonus" tolerance is added to the tolerance in the feature

control frame, yielding a total tolerance. For more information on

this bonus tolerance, see "Evaluating

Size with the Geometric Tolerance Command".

to indicate

the specification is at the least material condition (LMC). This means

that as the unrelated mating envelope size (or unrelated minimum material

envelope size for LMC) deviates from the MMC (or LMC), additional tolerance

or "bonus" tolerance is added to the tolerance in the feature

control frame, yielding a total tolerance. For more information on

this bonus tolerance, see "Evaluating

Size with the Geometric Tolerance Command".

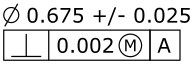

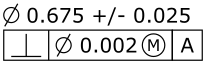

Suppose a cylindrical hole has a perpendicularity tolerance 0.002 at MMC, as shown here:

The size tolerance is 0.675 plus or minus 0.025, meaning the range of acceptable sizes is 0.650 to 0.700. The maximum material condition is then 0.650. If the unrelated measured mating envelope size is 0.661, then the bonus tolerance is 0.011, and the total tolerance is 0.013.

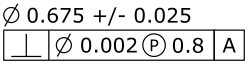

When the considered feature

is an auto feature cylinder, you can use a projected-zone modifier  as shown here:

as shown here:

This projects (extrapolates) the measured feature axis as described in "Deriving the Toleranced Feature".

When the considered feature

is a plane with surface data, you can use a tangent-plane modifier  ,

as shown here:

,

as shown here:

This makes the toleranced feature be a perfect-form plane tangent to the actual surface, as described in "Deriving the Toleranced Feature".

When the considered feature has surface data, and the toleranced feature differs from the considered feature’s surface data (cones, cylinders, and widths), the feature math type controls how to compute the toleranced feature from the considered feature’s surface data. For information, see "Deriving the Toleranced Feature”.

When at least one datum feature has surface data, the datum math type controls how to compute the measured datums from the datum features' surface data. For more information, see "How PC-DMIS Solves Datums".

Here is an example report for a perpendicularity tolerance. The cylinder's size tolerance is in the upper label, and the diametric-zone perpendicularity is in the lower label.