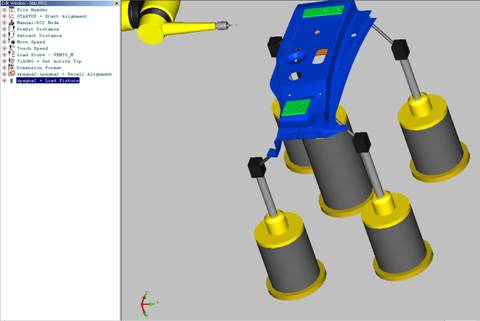

Fixtures are holding devices for manufactured parts and are often used in the automotive industry. Fixtures hold a part in the orientation that it is going to fit once it is on the car itself.

Graphical example of five flexible fixtures holding a car part

For example, a car door might have a fixture that holds a door at the hinge locations and then also at the latch on the other side. The door is placed in this holding device on the CMM and then it is inspected.

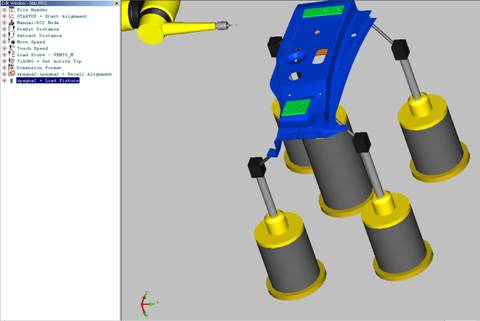

Basically, two parts create each flexible fixture.

The column: There may be several different sizes that handle the different areas within the workspace.

The module that fits on top of the column: These can be created from the standard set that the manufacturer supplies, or they can be custom designed to fit your specific needs. Many modules include clamps that hold the part to the module.

The end effector is an artifact placed against the part to hold it stationary in at least one axis. Typically, this is a sphere with a defined diameter. Spheres are used because they only contact the part at a single location. Other types of end effectors can be pins for mating holes, cylinders for locating edges, and special pieces that are specifically tailored to the part that the fixtures are holding.

The module is usually a cube with some geometry that is created in a specific way to contact the part in a predefined location.

See the graphical example below.

Graphical representation of the flexible fixture unit

A - Clamp

B - End Effector

C - Module

D - Column

When you create a new module, it gets saved to a file with the same name as the module, and it has a .module extension. A module definition stored to a file makes modules more reusable and distributable. Saved modules are then listed in the Modules section of the Fixture Properties dialog box (See "Fixture Properties - Modules".)

PC-DMIS supports both manual and DCC Flexible Fixturing systems with a single interface.

PC-DMIS uses a separate application called the Fixture Server Interface to actually define your fixture system, specify the parameters of your CMM, initialize the rack holding the columns, and monitor the status of your fixture system. See the "Using Fixturing System Setup" section for more information.

See the "Creating and Positioning Fixture Columns in PC-DMIS" topic for information about how to create and position the fixture columns.

You must be licensed or have the System V option programmed in your LMS license or portlock to work with DCC Fixturing systems and the 5 Unique option programmed to work with Manual Fixturing systems. You can use either the System V option or 5 Unique option, but not both at the same time, since these options are mutually exclusive.