Creating a 2D Radius Gage

To create a 2D Radius Gage with a Cross Section:

Create the cross section.

Select the Cross Section

Slide Show button ( )

from the Pointcloud toolbar (View

| Toolbars | Pointcloud) to view the cross section in a 2D

view.

)

from the Pointcloud toolbar (View

| Toolbars | Pointcloud) to view the cross section in a 2D

view.

Hold the Shift key down and point to the desired

radius. A display widget appears. The display widget shows the nominal,

measured, and deviation values for the radius.

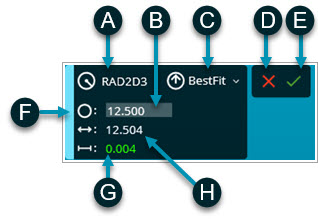

2D Radius Gage display widget

showing the nominal, measured and deviation values for the radius

Click to select the radius. A widget dialog

box appears.

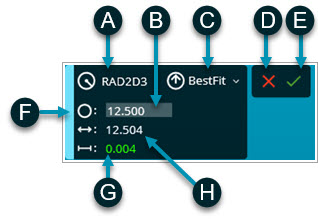

A

- 2D Radius Gage ID

B

- Radius nominal value

C

- Algorithm used to calculate the radius

D

- Cancel button

E

- Create button

F

- Use the handle to move the widget dialog box

G

- Radius deviation value

H

- Radius measured value

2D Radius Gage widget dialog

box

From the widget dialog box,

you can do the following:

Change the 2D Radius

Gage ID (A) and the nominal value (B).

From the list (C), select the algorithm the software uses to

calculate the radius.

Click the Create button (E) to

create the radius gage or the Cancel button

(D) to close the widget dialog box without

creating the radius gage.

Reposition the widget.

To do this, point to the handle on the left side of the widget (F). Click and drag the widget in the Graphic Display

window to reposition it.

When you create the 2D Radius Gage, PC-DMIS

creates its associated command in the Edit window. You can create

additional radius gages as needed.

Once you create a 2D Radius Gage, you can use it in

Location and Distance Dimensions, and Constructions. For Location Dimension,

Form is not supported.

To change the radius settings:

Edit them directly in the Edit window.

Click the radius gage command in the Edit window,

and then press F9 to open the 2D Radius Gage

dialog box to make your changes.

How the 2D Radius Gage is Calculated

Calculating the Nominal

2D Radius

Starting from the initial

picked measured point, the nominal radius is found on the nearest black

polyline. The software calculates the nominal (theoretical) radius for

a least square best fit circle, using all the nominal points that are

within 0.005 mm standard deviation.

Calculating the measured

2D Radius

The software calculates

a least square best fit circle, using the actual points on the yellow

polyline that are associated with the nominal points.

Starting from the initial

picked nominal point, the software finds the radius on the nearest black

polyline. The software calculates the nominal (theoretical) radius for

a least square best fit circle, using all the nominal points that are

within 0.005 mm standard deviation.

Starting from the initial

picked measured point, the software calculates the radius for a least

square best fit circle. The software uses all the measured points within

0.050 mm standard deviation and a search distance of 0.25 mm to find any

additional segments that belong to the radius.

More:

2D

Radius Gage Overview

2D

Radius Gage Dialog Box

)

from the Pointcloud toolbar (View

| Toolbars | Pointcloud) to view the cross section in a 2D

view.

)

from the Pointcloud toolbar (View

| Toolbars | Pointcloud) to view the cross section in a 2D

view.