Creating a Mesh/CAD Alignment

To create a Mesh to CAD alignment, do the following:

Ensure that you have an imported CAD model

in the Graphic Display window and a MESH

command in the measurement routine. These elements are required to

align a mesh to the CAD.

Select the Insert | Mesh

| Alignment menu option or select the Mesh

Alignment button ( )

on the Mesh toolbar. You can also access

this dialog box by typing the MESHCADBF

command in the Edit window’s Command mode between the ALIGNMENT/START

and the ALIGNMENT/END commands.

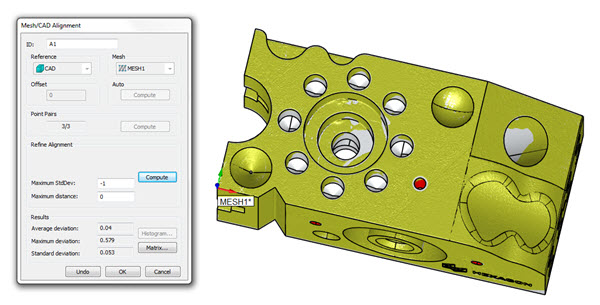

The Mesh/CAD alignment dialog box opens:

)

on the Mesh toolbar. You can also access

this dialog box by typing the MESHCADBF

command in the Edit window’s Command mode between the ALIGNMENT/START

and the ALIGNMENT/END commands.

The Mesh/CAD alignment dialog box opens:

Mesh/CAD Alignment dialog

box

For a complete description of

the Mesh/CAD Alignment dialog box, see the topic

"Mesh/CAD

Alignment Dialog Box Description" in the PC-DMIS Laser documentation.

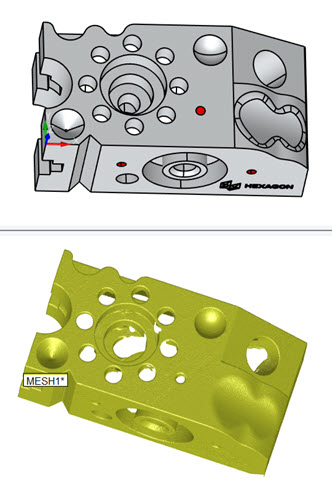

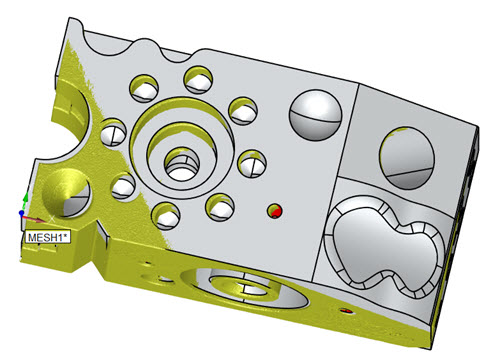

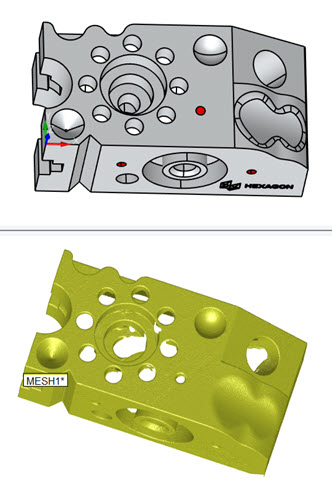

A temporary and split-screen view of the CAD

model and the mesh appears in the Graphic Display window. You can

use this split-screen view to visually see the alignment taking place.

From the Reference drop-down list, select

your point of reference; usually, either the CAD model itself or a

defined Mesh is available. The Mesh is aligned to the selected reference.

Split-screen view showing

the CAD model on the top view, and the mesh on the bottom view

If you have more than one mesh in your measurement

routine, from the Mesh list, choose the

mesh.

Perform the alignment:

In the Auto

section, click the Compute button. You should

use this only when you have a full scan of the external faces of the

part. This automatically performs an alignment of the Mesh to the

CAD and also a refinement on the alignment as it's generating.

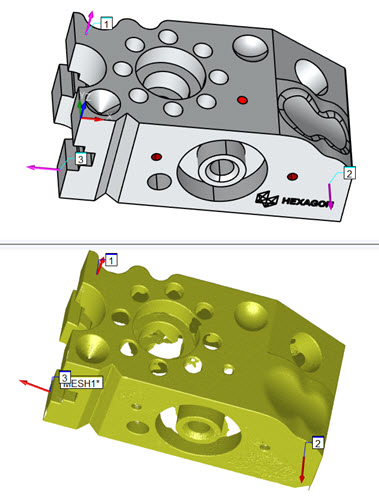

If the auto compute

does not compute a good alignment, use the Point

Pairs area to perform a rough alignment. This brings the mesh

close enough to the CAD if it's not already close. You can then refine

the alignment further if needed. You should use this type of alignment

if the mesh is not complete or if it contains scanned data that belongs

to a fixture, table, or other similar feature.

Click a desired

number of points on the mesh.

Click corresponding

locations on the CAD model.

The more points

you take around the different areas of the model and mesh, the better

the rough alignment.

Click Compute

to create the rough alignment.

Next, use the Refine Alignment area whenever you want to refine

your alignment. This brings the mesh closer to your CAD model. To

obtain a good refined alignment, the mesh points should be close enough

to the CAD points through an initial rough alignment.

In the Total

Points box, define the total number of random sample points

to use in each iteration.

In the Maximum

Iterations box, define the number of iterations.

In the Maximum

StdDev box, define the maximum standard deviation for the auto

alignment execution between the points in the mesh and the CAD model.

When the auto alignment command is executed, if the standard deviation

of the Mesh/CAD deviations is greater than the maximum value defined,

you can select point pairs to get a better alignment. The default

value of -1 is equivalent to an infinite allowed standard deviation.

Define the maximum

distance of the points from the CAD for use in the best fit routines.

The default value is 0. In this case, an internal max distance based

on the size of the mesh is used.

Click Compute

to refine the alignment.

If a portion of the mesh doesn't align nicely

with the CAD, you can click the Undo button

and recompute the alignment using the same type of alignment with

additional parameters; or you can try a different alignment.

If you have a surface model that represents

a sheet metal part, and you want to align to the offset faces, define

an Offset value that represents the constant

thickness of the sheet metal part.

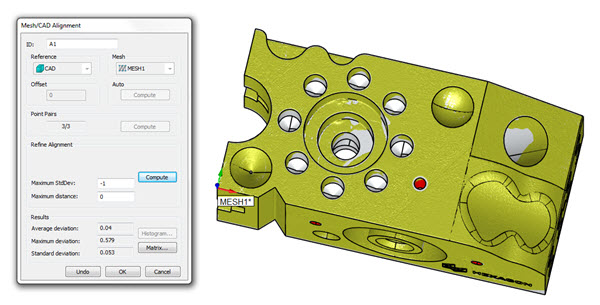

Use the Results area

to see how well the mesh aligned with the CAD. Make any changes to

the Offset or Refine

Alignment values to improve the alignment if necessary. If

any changes are made, be sure to click the Compute

button to regenerate the alignment with the new values.

Once you're satisfied with the alignment, click

Create. PC-DMIS closes the temporary split-screen

view and places the MESHCADBF command

in the Edit window. For information on the Edit window command, see

the "MESHCADBF

Command Mode Text" topic.

Example of a completed mesh

to CAD alignment

)

on the Mesh toolbar. You can also access

this dialog box by typing the MESHCADBF

command in the Edit window’s Command mode between the ALIGNMENT/START

and the ALIGNMENT/END commands.

The Mesh/CAD alignment dialog box opens:

)

on the Mesh toolbar. You can also access

this dialog box by typing the MESHCADBF

command in the Edit window’s Command mode between the ALIGNMENT/START

and the ALIGNMENT/END commands.

The Mesh/CAD alignment dialog box opens: