Creating and Configuring a Pallet Playlist

Similar to a playlist for music files, a playlist in

Inspect is a collection

of measurement routines that "play" (or execute) one after another.

With a pallet playlist, you can set up a grid of parts

for measurement. During execution, in each cell of the pallet grid, the

software executes a single routine. You can choose which routine each

cell executes when you begin the execution.

To begin, create

a playlist as usual and give it a name. If your playlist has more

than one part, PC-DMIS expects to find those parts in each cell on

the pallet.

From the playlist dialog box, in the Playlist Type list, choose Pallet

to show the Pallet Layout tab. The remaining

steps on this procedure use the Pallet Layout

tab.

Define the number of cells in pallet's grid

by defining the number of rows and columns:

Use the buttons on the right (or type in

the box) to define the number of rows.

Use the buttons on the bottom (or type

in the box) to define the number of columns.

Define the part offsets for the axes. By default,

the axes are X (across the grid's bottom) and Y (along the grid's

side). The axes appear red until you define the offsets:

Hover your mouse pointer over the red X

axis, and click the Part Offsets. Type

the part offset in X to the next part's origin, and press Enter.

Hover your mouse pointer over the red Y

axis, and click the Part Offsets. Type

the part offset in Y to the next part's origin, and press Enter.

When you type a non-zero

value for the axes, the red color goes away.

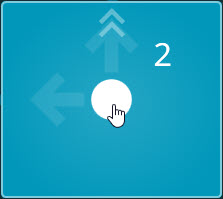

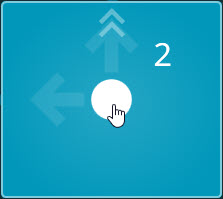

Set the start position (or origin):

Hover your mouse pointer over one of the

four corner cells that you want to be the start position. A large

white dot appears.

Click on the large white dot to set that

cell as the start position. You need to do this even if you want

to have the execution skip that corner cell.

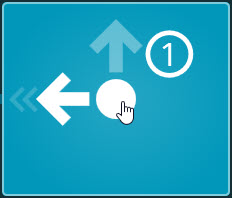

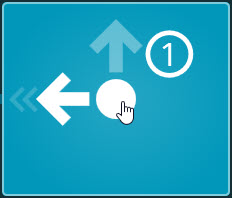

A number one, surrounded by a circle, indicates

the first cell. This is the start position:

Inspect

re-numbers the other cells.

During execution, the probe goes first

to the start position at cell number 1, it then moves to cell

number 2, and then to cell number 3, and so on.

Set the direction:

Hover your mouse pointer over the corner

cell that you chose as the start position.

Click the white dot to change the direction

that the probe follows during execution.

The large white arrow and the thick blue

lines and chevron arrows all update to indicate the new direction

the probe follows to measure the parts.

Turn off cells that you do not want to measure:

If you want the execution to skip any cells,

click on the blue background on that cell to turn that cell off.

A cell without a blue background is off.

You can click a background again to turn that cell back on and

show the blue background.

During execution, the probe moves above

any skipped cells, but it won't stop and measure within those

cells.

Ensure you have a working alignment for your

grid that matches your start position. You can do this in one of these

ways:

Option 1 - Perhaps the easiest way is to

have four external pre-defined alignment files (.aln), one for

each corner position. Then, whenever you change start positions,

you can select the alignment file for that start position.

From the gear button ( )

near cell 1, choose Using Pallet Alignment and

load your alignment file.

)

near cell 1, choose Using Pallet Alignment and

load your alignment file.

To create an external alignment,

measure the part once in the PC-DMIS software at that position. Then save

the routine out as an external alignment. If you need more information,

see the PC-DMIS documentation on external alignments.

Also, from the gear button,

define the Starting Offset values. If you have

multiple parts in your playlist, additional tabs appear so that you can

define offsets for each routine if needed. For more information, see the

description for Starting Offset in the "Pallet Layout Settings"

topic.

With Using

Pallet Alignment, the pallet is aligned using a pre-existing external

alignment. A start offset specifies the distance between the pallet origin

and the first part's origin. Subsequent parts are shifted by the pallet

size, relative to the first part. Pallet offsets are applied relative

to the reference manual alignment. Please

take care to orient this alignment to the pallet offset directions.

Option 2 - This option works with a single

measurement routine. In your routine, create a manual alignment

within the measurement routine for the part at the start position.

From the gear button ( )

near cell 1, choose Using Part Alignment.

With this approach, you must always use that start position. If

you do this, you do not need to choose an external alignment file.

)

near cell 1, choose Using Part Alignment.

With this approach, you must always use that start position. If

you do this, you do not need to choose an external alignment file.

The Run

Manual Alignment on First Part check box is available if your pallet

playlist only has one measurement routine. With this check box, Inspect only performs a manual

alignment on the first part in the grid. If you clear this check box,

it uses the existing manual alignment for each part. Be sure to manually

align each part to the first cell before you run the playlist.

If you need to define additional pallet settings

or actions, such as using a different alignment or offsetting the

start position by a certain amount, you can use the gear button near

cell 1. With the gear button, you can:

Change the pallet's axis reference

Define the alignment type (either pallet

or part)

Select an alignment file (for pallet alignments)

Set a starting offset (for pallet alignments)

For information on these

actions, see "Pallet Layout

Settings".

Click Save to save

the playlist and close the playlist dialog box.

Related Topics:

Pallet Requirements

Using

Pallet Playlists

Pallet Layout

Tab

Pallet

Layout Settings

Executing

a Pallet Playlist

)

near cell 1, choose

)

near cell 1, choose