Pointcloud Operator dialog box - SURFACE COLORMAP Operator

The SURFACE COLORMAP operation applies a colored shading to the CAD model. The model is shaded according to the deviations of the cloud of points compared to CAD. The model uses the colors defined in the Edit Dimension Color dialog box and the tolerance limits specified in the Upper tolerance and Lower tolerance boxes discussed below.

The colors used for the colormap are defined in Edit Dimension Color dialog box (Edit | Graphic Display Window | Dimension Color).

Select View | Other Windows | Dimensions Colors to view the color scale from the Dimensions Color Bar.

To apply the SURFACE COLORMAP operation to a Pointcloud,

click the Pointcloud Surface Colormap button

( )

on the Pointcloud toolbar (View

| Toolbars | Pointcloud), or select Insert |

Pointcloud | Surface Colormap.

)

on the Pointcloud toolbar (View

| Toolbars | Pointcloud), or select Insert |

Pointcloud | Surface Colormap.

Example of a Surface COLORMAP applied to selected CAD elements

The SURFACE COLORMAP operator has the following options:

Tolerances - Used to set the upper (Plus) and lower (Minus) tolerance values:

Plus - The upper tolerance value

Minus - The lower tolerance value

Use dimension color scale check box - When you select this check box, the software defines the color bar used for the Surface Colormap color properties by the Dimensions Color Bar. For details on the Dimensions Color Bar, see "Using the Dimensions Colors Window (Dimensions Color Bar)" in the "Using Other Windows, Editors, and Tools" chapter of the PC-DMIS Core documentation.

Edit Color Scale - When the Use dimension color

scale check box is cleared, the Edit Color Scale

button is enabled. When clicked, the functionality to dynamically change

the color, scale, and threshold of the surface and point colormap properties

becomes available through the Color Scale Editor

dialog box. For details, see the "Edit

the Color Scale" topic.

No data color check box - When you select this check box, the specified color is mapped to selected surfaces where no data is defined.

Refine Factor - This adjusts the accuracy of the Surface colormap. If you change this value, PC-DMIS draws a new and changed colormap. The underlying measured data does not change. The colormap tessellates the CAD model with an overlay of colored triangles. The vertices of each triangle are colored with the color that corresponds to its deviation from the pointcloud. The colors are taken from the dimensions color scale discussed above. By using a smaller or larger refine factor value, you can generate a finer or coarser tessellation, respectively. You may want to decrease the refine factor to obtain a smoothly shaded CAD with a more accurate deviation representation. However, setting a smaller refine value results in a larger number of triangles, thereby increasing the computation time and the size of the CAD model. For comparison, note that the number of triangles for a refine factor of 0.5, compared to a refine factor of 1.0, is about 4 times more; whereas a refine factor of 0.1 compared to 1.0, is about 100 times more.

Pointcloud

COLORMAP example with a Refine Factor of 1:

Pointcloud

COLORMAP example with a Refine Factor of 1:

Pointcloud

COLORMAP example with a Refine Factor of 0.1:

Pointcloud

COLORMAP example with a Refine Factor of 0.1:

Max distance - This value only allows points that fall within the max distance to be included in the colormap. Note that if this value is too small, you may not see all the expected colored deviations. A good rule of thumb is to set this value slightly larger (by 10% more, for example) than the largest deviation.

Thickness - This adds a thickness value to deviations on the colormap. This is useful if you want to add a material thickness to a CAD surface model.

Create annotation points check box - Annotations are a way to display the deviation for a specific location on a surface colormap with its associated color. To create an annotation:

Click the Create annotation points check box to select it. This clears the Select check box in the CAD Controls area and disables most of the options on the right side of the dialog box.

Select a point on the CAD surface in the Graphic Display window. PC-DMIS evaluates and creates an annotation label in the same background color as the COP deviation point with the deviation value. The label can be moved around in the Graphic Display window as any other label.

Once created, the annotation labels remain in the same position and have the same characteristics if the measurement routine is restarted, or if PC-DMIS is restarted and the same measurement routine is reloaded.

Create MinMax annotations check box - When this check box is selected, minimum and maximum values are created in the form of annotation labels for the active COP Surface Colormap.

The minimum and maximum points are recalculated each time the measurement routine is executed.

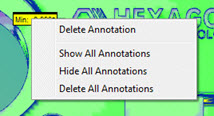

Show, Hide, or Delete Annotation Labels

To show, hide, or delete annotation labels, right-click one to display the pop-up menu and then select the appropriate option.

Delete Annotation - The selected annotation label is automatically deleted.

Show All Annotations - All annotation labels are displayed.

Hide All Annotations - All annotation labels are hidden.

Delete All Annotations - All annotation labels are automatically deleted.

Show annotation points check box - When this check box is selected, any annotation points that have been created are displayed.

Group - Use to create, modify, or identify Surface Colormap groups. For details, see "Method 2" in the "Apply COLORMAP to a CAD model with Multiple Surface Profile Tolerances" topic.

Click Abort to undo any calculations that were generated after you clicked the Apply button.

CAD Controls - Lets you apply the operation to selected CAD elements. See "CAD Controls", where scanning is discussed, for a more detailed description.

Click Create to insert a COP/OPER,SURFACE COLORMAP command into the Edit window.

For example:

COPFCOLMAP2=COP/OPER,SURFACE COLORMAP,PLUS TOLERANCE=0.25,MINUS TOLERANCE=-0.25,THICKNESS=0

REF,COP1,,

Colormaps in the Report

For information on how the software shows colormaps in the report, see "Colormaps and the CadReportObject" in the "Reporting Measurement Results" chapter of the PC-DMIS Core documentation.

More:

Apply COLORMAP to a CAD model with Multiple Surface Profile Tolerances

Dimensioning Surface Profile Using the Pointcloud Surface COLORMAP