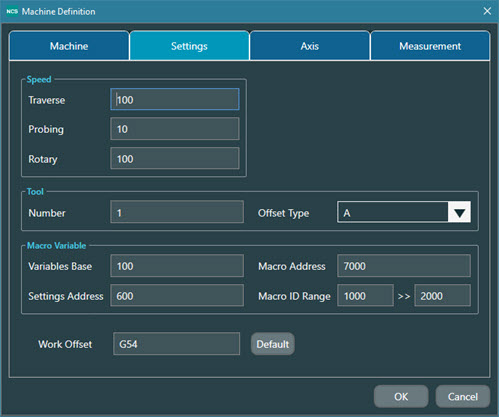

Machine Definition - Settings Tab

The Settings tab on the Machine Definitions dialog box provides settings that NC Server uses to generate macros, such as speeds and variables.

Speed area

Traverse - This defines the machine's maximum move speed in mm/minute or inch/minute, depending on the system units.

Probing - This defines the machine's probing speed in mm/minute or inch/minute, depending on the system units.

Rotary - This defines the machine's rotary speed in degrees/minute when the probe is in the spindle.

Tool Area

Number - This defines the machine's tool number.

Offset Type - This defines the tool table's offset type. The available options are:

A - The tool table only has one value per tool.

B - The tool table only has length and radius values.

C - The tool table allows length, radius, length wear, and radius wear values.

Macro Variable area

Variable Base - This is the starting value for local variables in CNC programs from NC Server.

Settings Address - This is the starting value for common variables that NC Server uses.

Macro Address - This is the starting value for system macros that NC Server uses.

Macro ID Range - This is the allowed range of macro numbers for CNC programs created by NC Server .

Work Offset

Work Offset - This defines the work offset to use at the beginning of a CNC program.