How To Measure a Cylinder (Boss)

Note

Note that the Learn then Measure box is active.

Instructions | |||||

|---|---|---|---|---|---|

1 |

| Position the probe next to the point at the bottom level of the cylinder and press the Read Position button. |

| ||

2 |

| If at any time you need to correct the position, press the Remove Last Position button to cancel the previously read location, then repeat the previous step. | |||

3 |

| Position the probe next to the point at the top of the cylinder and press the Read Position button. |

| ||

4 |

| Position the probe over the center of the cylinder at a safe height and press the Read Position button. IMPORTANTYou must position the probe close to the center of the feature. If you don't, a crash could occur. |

| ||

5 |

| Position the probe for an automatic measurement and press the Execute button. Start the monitor macro on the machine. NC Gage uses four points to find the cylinder. Then NC Gage measures four points on the bottom and top levels to calculate the diameter and the angles to the axes. | |||

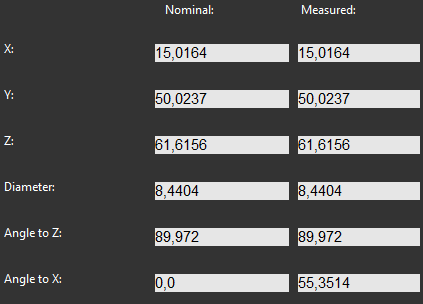

6 | Review the measured values on the screen and make any adjustments to the nominal values if necessary.

| ||||

7 |

| Press OK to add the command to the measurement program. | |||