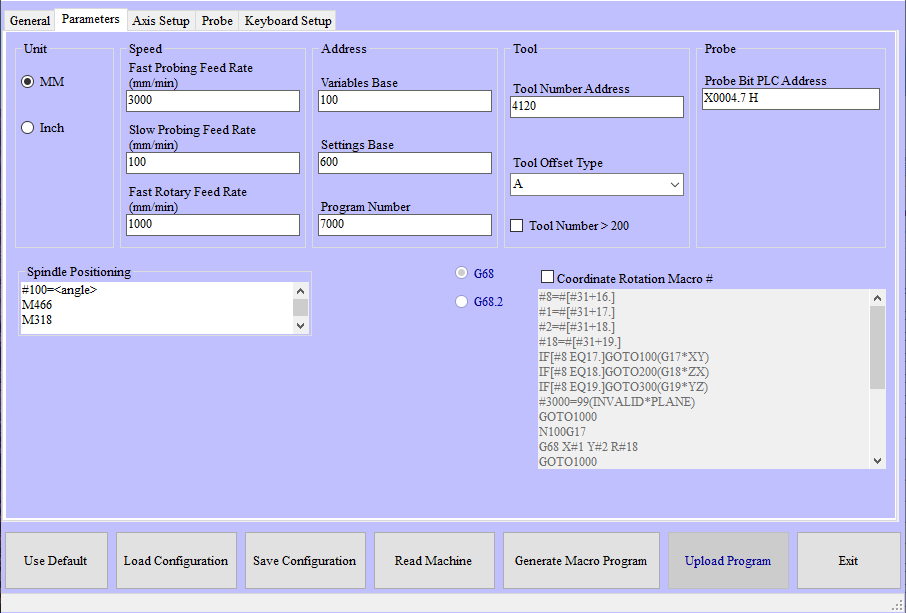

Setting the Values on the Parameters Tab

NC Gage Parameters Tab

Required Parameters | |

|---|---|

Step | Instructions |

1 | Verify the operating units of the machine (Inch / mm) |

2 | Set the Speeds:

|

3 | Set the variable and program addresses:

|

4 | Verify the Tool / Tool Table information:

|

5 | Verify the Spindle Positioning commands:

TipYou can leave the Spindle Positioning parameter field empty. This will disable the “Find Sphere” and “Find Ring” functions in NC Gage. You can leave the Unclamp and Clamp parameter fields blank if your machine does not require them. |

Optional Parameters | |

|---|---|

Steps | Instructions |

NoteThese items are not required for the operation of the software, but may be required for use with certain options or other systems. | |

1 | Coordinate Rotation Macro - This defines the content of a user macro that you can use to update the coordinate rotation values with G11. |